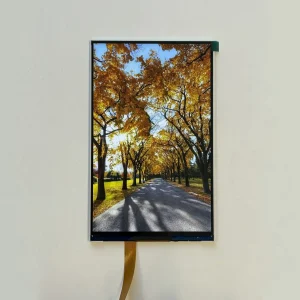

Introducing Rocktech 7″ MIPI Panel – 800×1280 High Resolution TFT Display

Overview of the 7 Inch IPS Display with 800×1280 Resolution During the past few years, the requirement of high resolution TFT display has been experiencing further expansion in industrial, medical, and smart device sectors due...