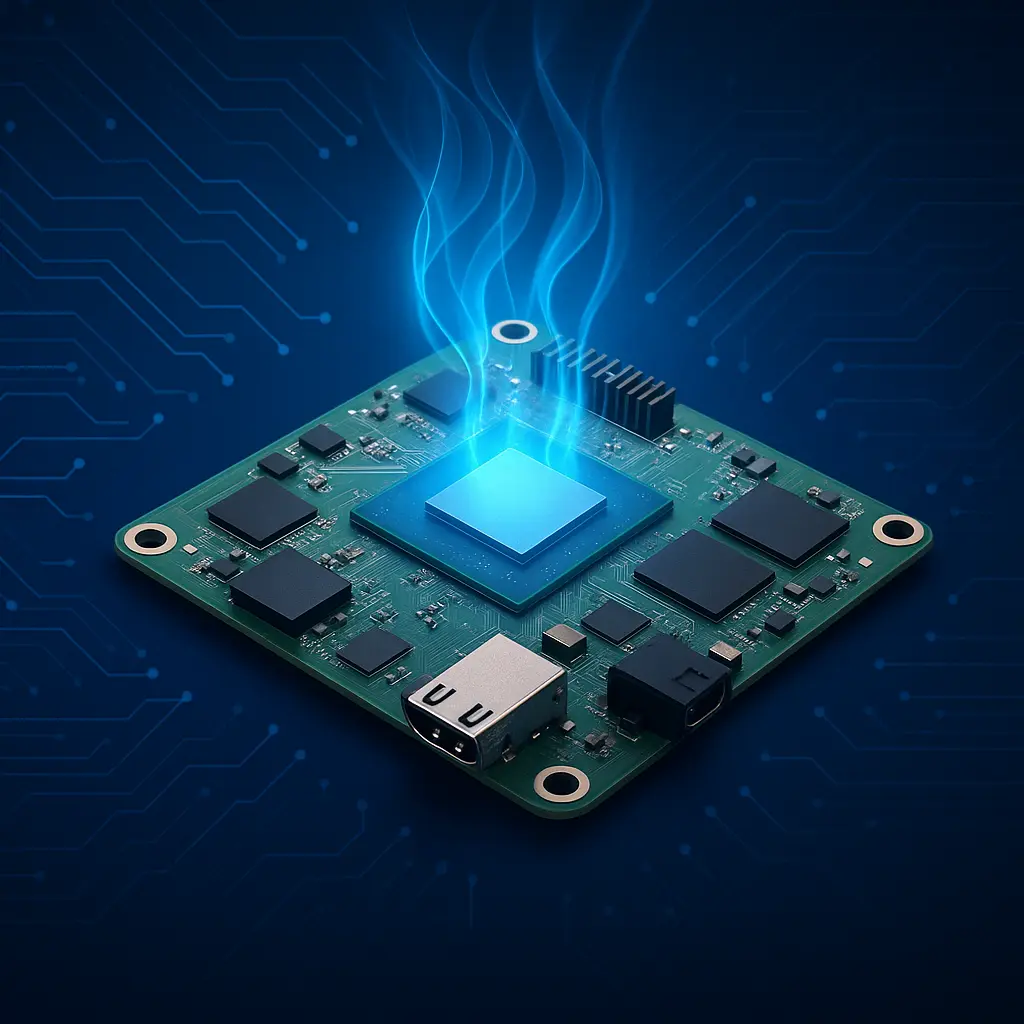

Embedded systems powered by single board computers (SBCs) are increasingly used in industrial automation, IoT, automotive, and smart home devices. While performance continues to rise, the tradeoff is often higher power consumption and more heat. Excess heat not only reduces efficiency but can also shorten the lifespan of sensitive components. In compact housings or outdoor environments, thermal stress may even trigger crashes, instability, or permanent damage.

Why Temperature Control Matters in Embedded Systems

Temperature plays a critical role in the reliability of electronics. Once operating heat rises beyond a safe threshold, several issues can occur:

- Performance throttling: SoCs (System on Chips) often reduce frequency to avoid thermal damage, leading to noticeable slowdowns.

- Component degradation: DDR memory, NAND flash, and PMICs wear out faster when running hot for long periods.

- System instability: Random resets, corrupted data, and weakened signal integrity can all trace back to excessive heat.

- User safety concerns: A hot device surface or display makes products uncomfortable to touch and may even raise safety risks.

Therefore, controlling and lowering the temperature is crucial not only for performance but also for ensuring long-term stability and reliability of embedded devices.

Identifying Major Heat Sources in Embedded Systems

To effectively lower temperature, the first step is identifying where most of the heat originates. In embedded systems with SBCs and TFT displays, the main culprits usually include:

- TFT backlight: LED backlights in LCD panels consume significant power. In high-brightness displays, backlight drivers can generate more heat than the SoC itself.

- SoC (CPU/GPU/NPU): The central processor is typically the hottest component when the system is under load.

- DDR (Memory): Continuous data access and high-frequency memory clocks generate substantial thermal energy.

- Flash storage: Intensive read/write cycles cause NAND flash chips to heat up, especially during system updates or logging operations.

- Peripheral ICs: Wi-Fi, Bluetooth, power regulators, and other interface chips also contribute to heat, though to a lesser extent.

Software Strategies for Lowering Temperature

Not all heat problems require hardware fixes. In fact, software optimization is often the easiest way to cut down unnecessary power usage and keep SBCs cooler:

1. Backlight Management

For devices with TFT LCD panels, backlight control is essential:

- Automatically reduce brightness when not needed.

- Turn off the backlight completely during idle or standby periods.

- Use PWM dimming strategies to balance visibility and power savings.

2. Dynamic Frequency and Voltage Scaling (DVFS)

Modern SoCs support dynamic frequency scaling:

- Reduce CPU/GPU frequency when full performance is not required.

- Automatically adjust voltage to match performance demands, lowering overall power consumption.

- Disable unused CPU cores in low-power mode.

3. Kernel and System Optimization

- Remove unnecessary kernel modules and services to minimize background processes.

- Use lightweight operating system builds (such as Buildroot or Yocto with minimal packages) to reduce resource usage.

- Implement efficient scheduling to avoid running multiple heavy tasks simultaneously.

4. Application-Level Optimization

Applications themselves can also be optimized:

- Reduce redundant computations and avoid resource-heavy animations or effects.

- Limit background services to essential functions only.

- Use hardware acceleration (GPU/NPU) where possible, since optimized hardware consumes less power than inefficient software loops.

5. Power Gating for Peripherals

If certain hardware is not being used (e.g., USB, camera, or Wi-Fi modules), completely shut down or suspend their power supply instead of leaving them idle.

This prevents unnecessary heat buildup.

Hardware and Structural Solutions

Of course, software alone cannot solve every overheating issue. The way you design hardware and the device housing also makes a huge difference in thermal performance:

1. Passive Cooling

- Heatsinks: Attach aluminum or copper heatsinks to the SoC, DDR, and power ICs to quickly spread out heat.

- Thermal pads and conductive films: Transfer heat from chips to the enclosure or a larger heat-dissipating surface.

- PCB layout optimization: Use thicker copper layers and thermal vias under power components for better conduction.

2. Active Cooling

- In high-power applications, add small fans or blowers to improve airflow.

- Use intelligent fan control so cooling is only active when necessary.

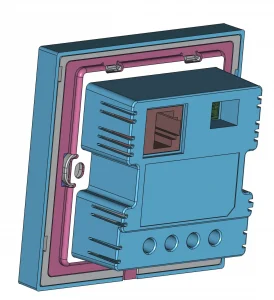

3. Housing Design

- Ventilation channels: Proper airflow paths within the housing help dissipate hot air naturally.

- Material selection: Use metal enclosures or hybrid structures to improve heat conduction.

- Compact vs. open design: In compact enclosures, consider additional ventilation holes or external heat spreaders.

4. Environmental Considerations

- Place devices away from direct sunlight or heat sources.

- For outdoor applications, consider weatherproof but thermally conductive enclosures.

Balancing Performance and Thermal Management

Cooling strategies should never be about blindly reducing performance. The goal is balance—making sure the system runs within safe temperature ranges without losing critical speed or responsiveness. The goal is to balance performance with acceptable temperature levels:

- For mission-critical applications, ensure the system can run at full load without exceeding safe limits.

- For less demanding use cases, prioritize energy efficiency and thermal safety over maximum processing power.

- Perform regular thermal profiling during development to test worst-case scenarios and validate thermal solutions.

Conclusion

In the end, thermal management for embedded systems is a multi-layered approach. Smart software control helps prevent heat before it builds up, while solid hardware design ensures the remaining heat has a clear path out. From optimizing backlight usage and enabling dynamic frequency scaling, to shutting down unused peripherals and streamlining applications, software provides the first line of defense. Meanwhile, hardware strategies such as heatsinks, ventilation design, and thermal conduction materials guarantee that the heat which is inevitably generated can be efficiently dissipated. By addressing heat sources at every level—from SoCs and DDR to TFT backlights and enclosures—developers can create reliable SBC-based devices that stay cool, stable, and safe, even under tough operating environments.