When it comes to choosing between Industrial Displays and consumer-grade displays, understanding the differences is critical, especially for system integrators, product designers, and OEMs working in industrial or embedded sectors. This guide outlines the key distinctions, performance criteria, and decision-making points to help you make the right choice for your application.

What Are Industrial TFT Displays?

Defining Industrial TFT Displays

Industrial TFT (Thin-Film Transistor) displays are designed for demanding applications that require consistent performance in harsh environments. These displays are engineered with durability, longevity, and environmental resistance in mind, making them essential for sectors such as manufacturing, automation, energy, transportation, and medical equipment.

Common Use Cases for Industrial Displays

Industrial displays are commonly used in:

- Factory automation systems

- Outdoor kiosks and vending machines

- Medical and diagnostic devices

- Agricultural and heavy machinery displays

- Marine and transportation systems

- Energy and power monitoring equipment

These applications demand features far beyond what typical consumer displays can provide.

Industrial Displays vs Consumer Displays: What’s the Difference?

Rugged Construction and Long-Term Reliability

Industrial TFTs are built with reinforced housings, robust backlights, and industrial-grade components that can withstand shocks, vibrations, and extended usage cycles.

Longevity and Product Lifecycle Management

Most industrial display manufacturers ensure long-term availability (5-7+ years), with strict revision control and minimal design changes—unlike consumer displays that change models every 6–12 months.

Environmental Resistance

Industrial displays are often designed to function reliably in extreme temperatures (from -20°C to +75°C), direct sunlight (high-brightness readability), and high-humidity conditions.

System Integration and Connectivity Flexibility

Industrial TFTs are designed to fit into diverse embedded systems. They support a range of signal interfaces and mounting options, enabling direct integration with industrial PCs, single board computers, and PLCs.

Common features include:

-

Wide input voltage support

-

Signal interfaces like LVDS, RGB, SPI, UART, or parallel interfaces

-

Optional touch input (resistive or capacitive) with industrial controller ICs

-

Mechanical design flexibility: open frame, panel mount, VESA mount, etc.

Consumer displays, by contrast, are limited to standardized video interfaces like HDMI or DisplayPort, and are not suitable for embedded or space-constrained applications.

Side-by-Side Feature Comparison

| Feature | Industrial TFT Display | Consumer TFT Display |

|---|---|---|

| Operating Temperature | -20°C to +70°C | 0°C to 40°C |

| Brightness | 300–1500 nits | 200–400 nits |

| Touchscreen Options | PCAP / RTP, Glove Support, Water Resistance | PCAP only |

| Interface Compatibility | LVDS, RGB, SPI, eDP | HDMI, MIPI DSI |

| Product Lifecycle | 3–5+ years | 6–18 months |

| Customization | High (cover lens, brightness, size, interface) | Low |

Performance and Visual Clarity in Demanding Conditions

Sunlight Readability and High Brightness

Industrial TFTs often provide brightness ratings above 1000 nits, which ensures readability under direct sunlight—ideal for outdoor kiosks, marine panels, or automotive dashboards.

Wide Operating Temperature Range

Displays in factory floors or outdoor locations need to function across wide temperature fluctuations. Industrial displays maintain performance even in -30°C cold or 85°C heat.

Enhanced Durability and Shock Resistance

Industrial TFTs are tested for vibration and impact resistance, with compliance to industry standards such as IEC 60068.

Why Custom TFT Displays Matter in Industrial Applications

Tailored Design for Specific Needs

Unlike consumer products, industrial projects often require displays tailored to fit specific enclosures, control boards, or user environments. A reliable TFT LCD manufacturer will offer custom TFT displays services such as:

- Custom cover glass with silk printing, anti-glare, anti-reflection coatings

- Custom brightness levels (e.g., 1200 nits for outdoor applications)

- Touch panel tuning for gloves or water resistance

- Custom interface pinout or FPC layout

- Optical bonding or conformal coating for rugged use

- Shape or dimension modification (e.g., ultra-wide displays)

These customizations help ensure the display not only fits the system mechanically and electrically but also delivers optimal usability in its operating context.

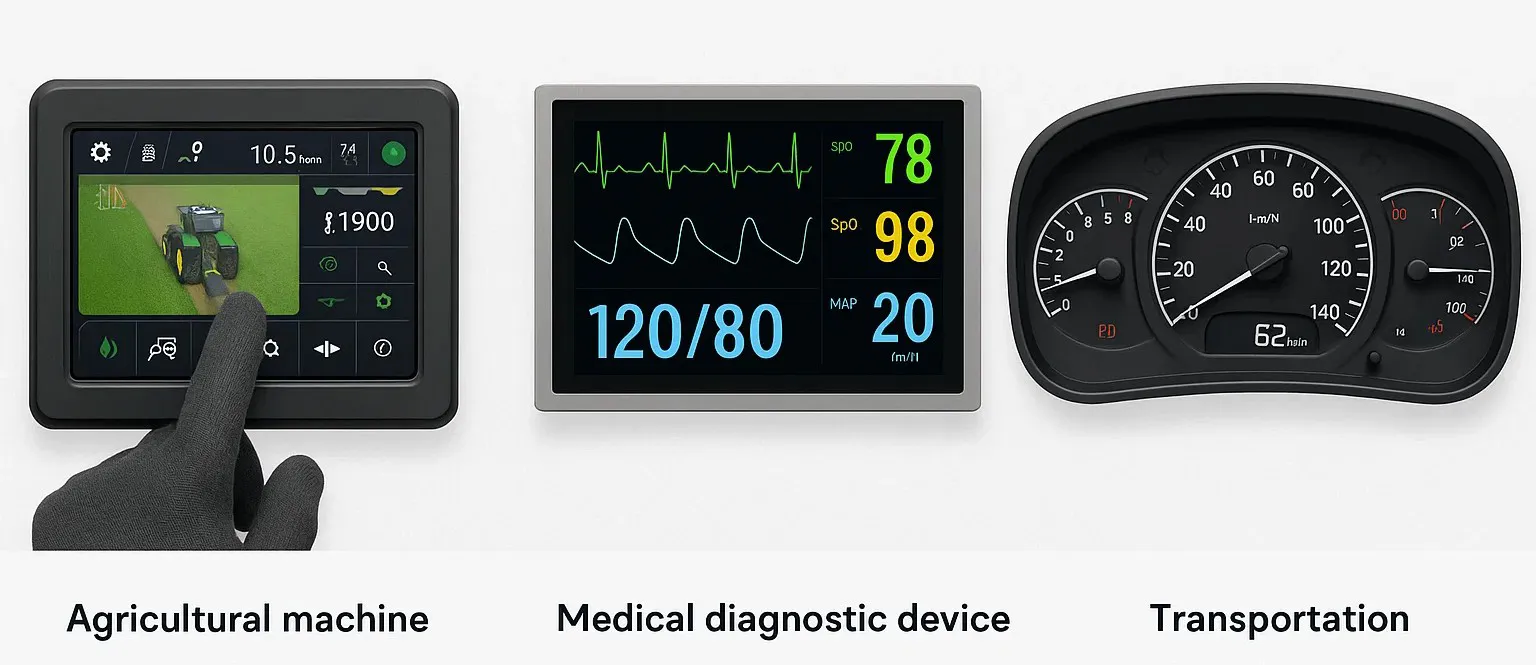

Application-Specific Examples

- In agricultural machines, custom displays with high brightness, glove-friendly touch, and waterproof design help operators manage complex interfaces in open-field environments.

- In medical diagnostic devices, displays with custom brightness and viewing angles ensure accurate data visibility across varying ambient conditions.

- In transportation, conformal coating and custom pin configurations allow better vibration and EMI protection.

Industrial Displays Application

Industrial Displays Application

Choosing the Right TFT LCD Manufacturer

What to Look For in an Industrial Displays Supplier

To ensure product quality and project longevity, it’s important to partner with an experienced TFT LCD manufacturer that understands industrial requirements.

Key factors to consider:

- Long-term supply chain support

- Experience with custom TFT display projects

- Transparent communication and technical documentation

Benefits of Working with Custom TFT Displays Experts

Partnering with a manufacturer who specializes in industrial and custom TFT display solutions helps you:

- Reduce integration risk

- Accelerate time-to-market

- Improve user experience and reliability

Industrial TFT displays are not just about durability but about designing for reliability, clarity, and long-term success in demanding environments. When choosing between industrial displays vs consumer displays, remember that short-term savings on display costs can lead to long-term setbacks in maintenance, replacements, or system failures.

Whether you’re developing a next-gen HMI panel, upgrading outdoor control systems, or building rugged medical equipment, working with a trusted TFT LCD manufacturer and exploring custom TFT display options can give you the edge in performance and longevity.