Introduction to EMI Protection Displays and EMI LCD Technology

Defining EMI and Its Relevance to EMI Shielding LCD

Electromagnetic Interference (EMI) refers to the disruption of electronic signals caused by external electromagnetic waves. In modern electronics, especially displays, EMI can lead to unstable performance such as flickering, signal distortion, or even touch malfunction. This makes EMI particularly relevant to EMI LCD technology, where clear visual output and responsive touch are essential. To address these challenges, an EMI shielding LCD integrates conductive films or layers that block or absorb interference, ensuring stable performance in demanding environments such as automotive, aerospace, and industrial applications.

Why EMI Protection Displays Are Critical for Industrial TFT Displays

As display technology evolves, industries increasingly require custom displays tailored to specific needs—ranging from precision medical equipment to rugged industrial TFT displays used in harsh environments. However, without effective EMI protection, even the most advanced display can suffer from reduced reliability and regulatory non-compliance. EMI Protection Displays solve this issue by safeguarding system stability, maintaining touch accuracy, and ensuring compliance with global EMC standards. For manufacturers and end-users alike, EMI shielding is not just a technical upgrade but a necessity to deliver dependable, high-performance display solutions across various sectors.

Sources and Impact of EMI

Common EMI Sources

Electromagnetic Interference is generated by a variety of technologies and equipment. The most frequent sources include:

| Category | Examples |

|---|---|

| Wireless Communication Systems | Wi-Fi, Bluetooth, 4G/5G networks |

| Power Supplies & Chargers | Switching power supplies, chargers |

| Industrial Equipment | Motors, inverters, factory automation systems |

| Automotive Electronics | Electric vehicles, ADAS systems |

| Medical & Scientific Devices | Devices operating with high-frequency signals |

These sources are widespread and can create challenges for displays if not properly addressed.

How EMI Causes Performance Issues in Industrial TFT Displays

When exposed to these interference sources, a LCD without adequate protection may experience visible and functional issues. Typical problems include:

-

Flickering or unstable brightness

-

Distorted or noisy images

-

Touch malfunctions, such as delayed or inaccurate response

-

Reduced overall reliability of the system

This impact is especially critical for industrial TFT displays, which are often deployed in harsh environments with heavy electrical noise. For example, in factories or power systems, strong EMI from motors and inverters can significantly degrade display performance. By integrating shielding films, coatings, or conductive layers, an EMI LCD effectively reflects or absorbs interference, maintaining stability even in electrically noisy surroundings.

Compliance Standards for EMI LCD

To ensure safety and interoperability, EMI Protection Displays must comply with strict international standards. Certifications such as FCC (U.S.), CE (Europe), CISPR, and IEC 61000 define acceptable EMI emission levels and immunity thresholds. Meeting these compliance standards is particularly important for custom displays used in regulated industries like aerospace, automotive, and healthcare. An EMI shielding LCD that passes these certifications not only guarantees stable performance but also speeds up product approval in global markets, reducing risks for manufacturers and end-users.

EMI Shielding Films and Their Role in EMI Protection Displays

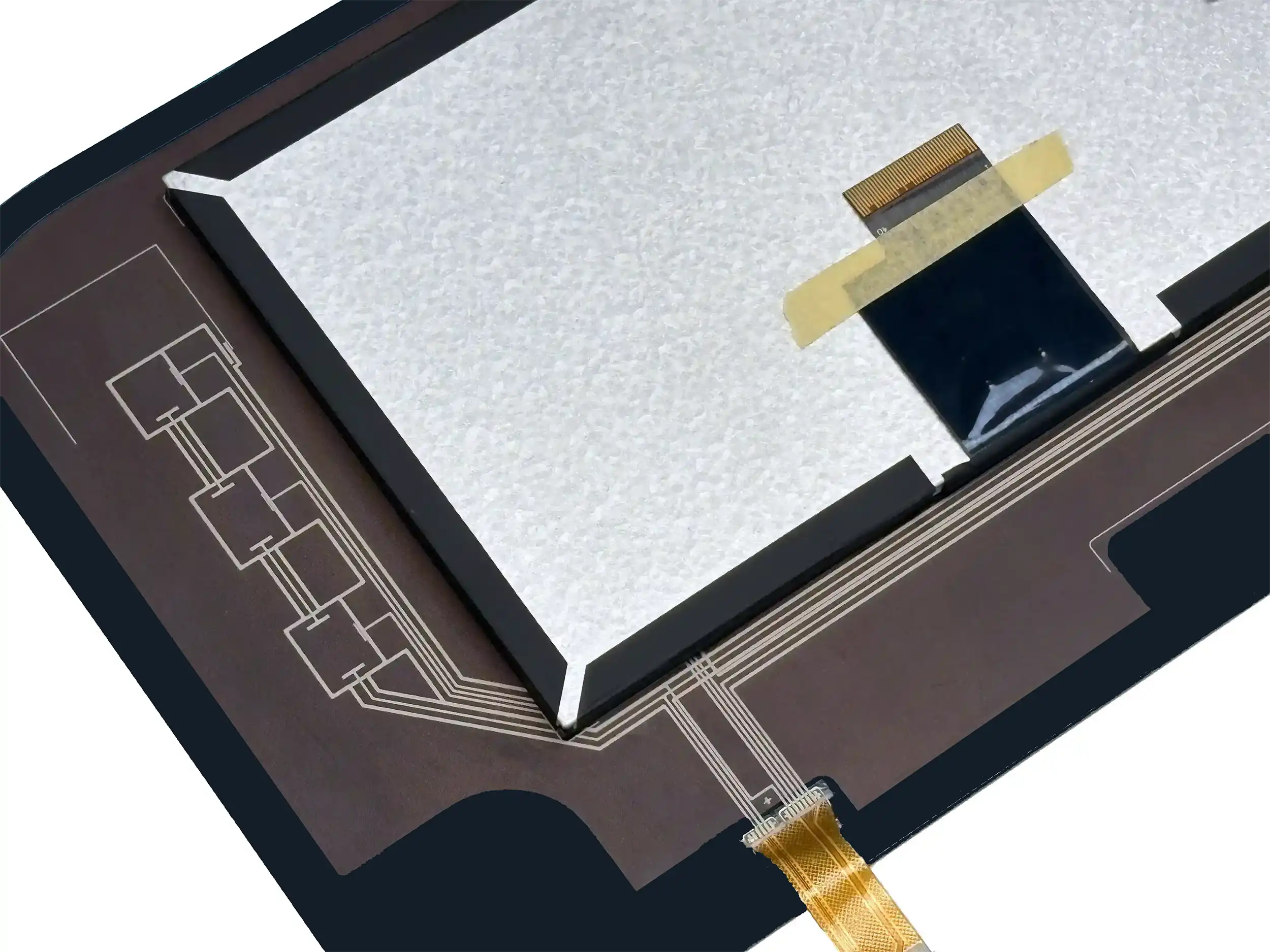

Materials and Design of EMI Shielding LCD

EMI Protection Displays use EMI shielding films made from conductive materials such as ITO, metal mesh, or advanced nanomaterials like silver and copper. These films combine excellent conductivity with high transparency and flexibility, making them ideal for integration into industrial TFT displays. The design of the shielding film ensures effective electromagnetic protection while maintaining display brightness and touch sensitivity.

Working Principles of EMI Shielding Films

The working principle of EMI shielding films is rooted in electromagnetics. When electromagnetic waves (such as radio frequency or microwaves) encounter the shielding layer, the conductive material reflects, absorbs, or disperses the energy. Part of the interference is absorbed and converted into heat, while the rest is safely guided to ground through the conductive layer. Multi-layer structures further enhance this effect, effectively decoupling external EMI and preventing it from disturbing display circuits or nearby components.

Key Functions for EMI Shielding LCD

The integration of shielding films provides several critical benefits:

1. Electromagnetic Shielding

- Prevents external interference (e.g., Wi-Fi, 5G, Bluetooth) from affecting display drivers, reducing risks of flicker, noise, or touch malfunction.

- Suppresses internal emissions from the display itself (e.g., high-frequency LCD/OLED drivers) that could disrupt nearby components like antennas or cameras.

2. Signal Integrity Protection

- Minimizes crosstalk in high-speed interfaces such as eDP or LVDS.

- Ensures stable data transmission and reduces the likelihood of errors or distortions.

Through these mechanisms, EMI Shielding Film enhances reliability, maintains touch accuracy, and safeguards the long-term stability of displays operating in high-EMI environments.

Applications for Industrial EMI Protection Displays

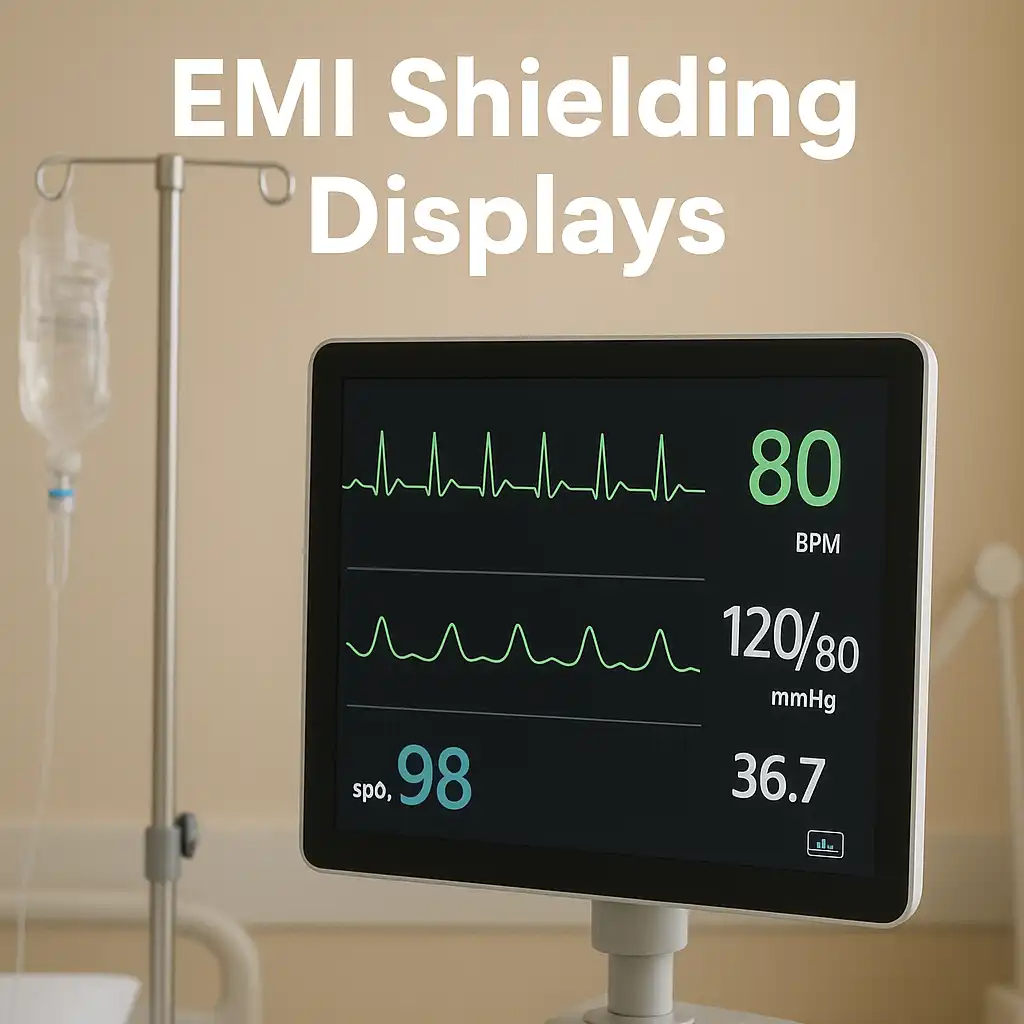

Medical Devices Using EMI Protection Displays

Medical equipment requires precise and reliable displays, as even minor interference can affect diagnostics or treatment. EMI Shielding LCD in medical devices help prevent external electromagnetic noise from disrupting visual output or touch functionality. EMI LCD panels are especially critical in imaging devices, patient monitors, and laboratory instruments, ensuring accurate data presentation and patient safety.

Industrial TFT Displays in Harsh EMI Environments

Factories, power plants, and automation systems generate strong electromagnetic fields that can compromise display performance. Industrial TFT displays equipped with EMI shielding designs maintain stability in these challenging environments, protecting both visual clarity and touch accuracy. These displays are ideal for control panels, human-machine interfaces (HMI), and monitoring systems.

EMI LCD for EV and ADAS Systems in Automotive

Electric vehicles (EVs) and advanced driver-assistance systems (ADAS) operate in electrically noisy conditions with high-speed electronics. EMI LCD panel ensures in-vehicle displays remain free from flicker, signal distortion, or touch errors, providing reliable performance for dashboards, infotainment systems, and driver assistance interfaces.

Smart Devices and Communication Equipment with Custom Displays

Consumer electronics and communication devices, including smartphones, tablets, and IoT terminals, increasingly integrate custom displays with EMI protection. These EMI Protection Displays prevent interference from Wi-Fi, 5G, Bluetooth, and other high-frequency signals, ensuring smooth operation, data integrity, and enhanced user experience.

Future Trends in EMI Protection Displays and Materials

Materials and Sustainability

Advanced conductive materials, such as silver nanowires and graphene, enhance EMI LCD by offering high conductivity, transparency, and flexibility. Eco-friendly films and recyclable coatings are increasingly applied in industrial TFT displays, reducing environmental impact while maintaining performance.

Integration and High-Frequency Challenges

EMI Protection Displays are moving toward integrated modules combining LCD, touch, and shielding, improving reliability and saving space in automotive, medical, and industrial applications. With 5G and future 6G networks, shielding must handle higher-frequency EMI while keeping display clarity and touch accuracy.

Conclusion: The Importance of EMI Protection for Custom Displays

EMI Protection Displays are essential for maintaining stability and reliability in high-performance display systems. By shielding against electromagnetic interference, they prevent flicker, signal distortion, and touch malfunctions, ensuring consistent performance even in demanding environments.

Offering custom displays with tailored EMI shielding is crucial for industries such as medical, automotive, aerospace, and industrial automation. These custom EMI shielding LCD not only meet regulatory compliance but also deliver optimal functionality, reliability, and user experience across diverse applications.