What Is a Sunlight Readable Display?

Sunlight readable displays are specially engineered LCD screens designed to remain visible under strong ambient light. They achieve this through two main approaches: transflective technology and high brightness backlighting.

1. Introduction: The Challenge of Outdoor Visibility

In today’s connected world, sunlight readable displays are essential in outdoor environments — from handheld devices to outdoor kiosks, industrial machines, and automotive dashboards. But one challenge continues to frustrate users and designers alike: poor visibility under direct sunlight.

When a display is used in bright outdoor environments, it often appears washed out or dim. This isn’t because the display suddenly got weaker — it’s largely due to how our eyes respond to strong ambient light. In intense sunlight, the human eye naturally reduces the size of the pupil to protect the retina, limiting the amount of light that enters. As a result, even a normally bright TFT LCD may appear too dark to read.

This is where the concept of a sunlight readable display becomes essential. Far from being a luxury, high-visibility screens are a critical requirement in a wide range of applications — especially in industrial, medical, outdoor retail, and automotive sectors.

2. Why Do Screens Appear Dim Without a Sunlight Readable Display?

To understand why screens struggle outdoors, we need to consider the competition between ambient light and the display’s own brightness. The stronger the surrounding light, the harder it becomes for the screen to maintain contrast and visibility. This is known as low perceived contrast ratio.

Our eyes further compound this issue. In bright environments, the iris contracts to reduce the light entering the eye. While this is a natural defense mechanism, it also reduces the perceived brightness of displays, even if the screen itself hasn’t changed. A standard TFT LCD panel that looks perfectly fine indoors may seem underpowered and dull in daylight.

This visual degradation is not a flaw of TFT technology itself, but rather a mismatch between display brightness and ambient conditions. To solve this, engineers have developed technologies that make LCD screens truly visible — and even brilliant — in direct sunlight. These are known as sunlight readable displays, and they come in several different forms.

3. Two Approaches to Sunlight Readability

To overcome the limitations of standard TFT LCDs in outdoor environments, engineers have developed two main strategies. Each method enhances screen readability under sunlight in a different way, offering trade-offs between performance, power consumption, and cost.

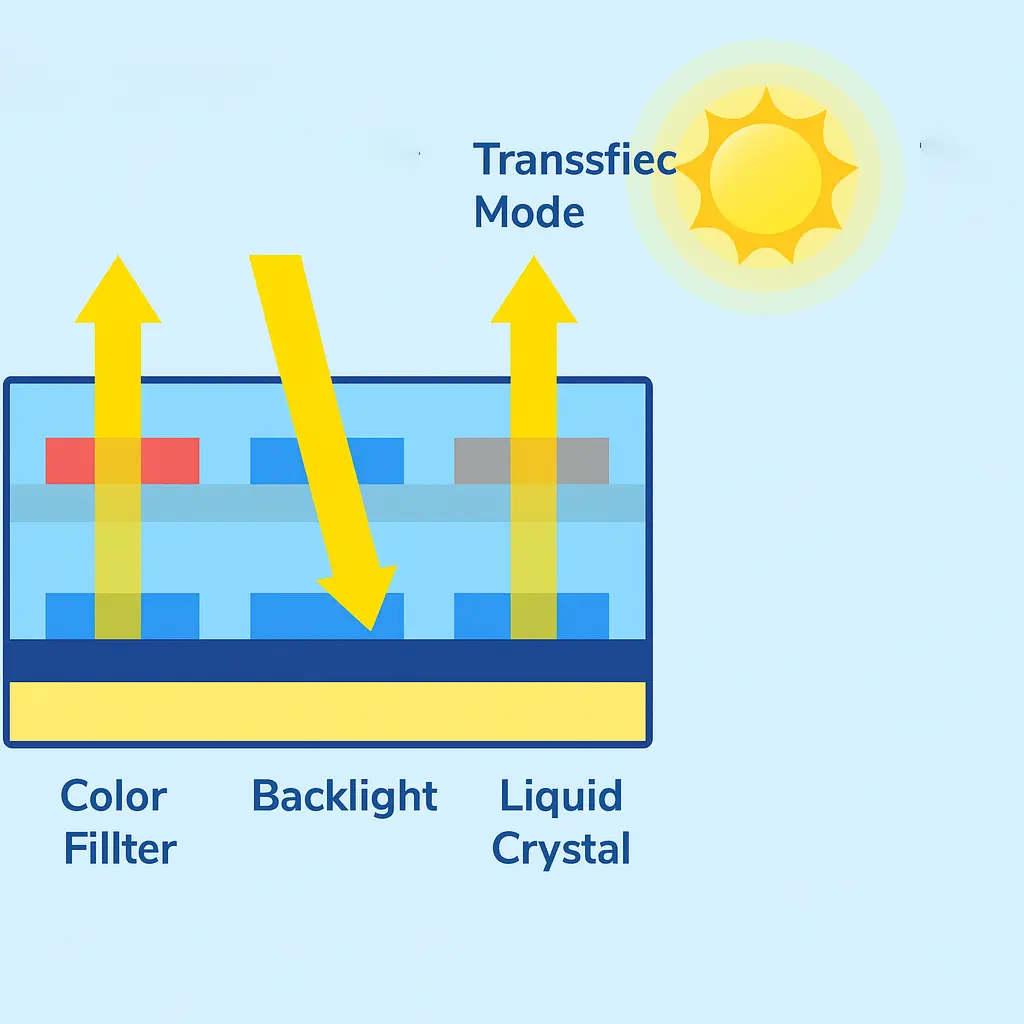

3.1. Transflective TFT Technology

Transflective displays combine both transmissive and reflective properties. In normal conditions, they function like regular transmissive LCDs using a backlight. But when exposed to strong ambient light — especially direct sunlight — a reflective layer behind the LCD reflects incoming light back through the display, effectively boosting its visibility.

- Working Principle: Transflective panels use ambient light as a secondary light source by reflecting it back toward the viewer.

- Benefit: The stronger the ambient light, the more light is reflected — making the display more readable under intense sunlight.

- Advantages: Low power consumption, excellent readability under bright conditions, ideal for battery-powered outdoor devices.

- Limitations: Color reproduction is generally weaker than full transmissive displays, and manufacturing cost can be slightly higher.

3.2. High Brightness Display: Backlight Enhancement Techniques

Another approach is to increase the display’s active brightness by enhancing the LED backlight. A typical indoor TFT screen has a brightness level of 250–400 nits, which is insufficient for outdoor use. High brightness displays — also known as daylight readable displays — usually target brightness levels of 800 nits or more to function effectively as sunlight readable displays.

- Working Principle: By increasing the number and intensity of LEDs behind the LCD panel, the display becomes strong enough to overcome ambient light interference.

- Advantages: Standard TFT glass can still be used, meaning most of the cost is concentrated in the backlight module. This allows manufacturers to reuse existing display designs and only optimize the backlight system, making it a cost-effective upgrade.

- Limitations: Enhanced backlights generate more heat and require additional space for heat dissipation and LED placement. As a result, the overall module thickness may increase, which could be a concern for slim industrial or portable designs.

4. Techniques to Increase Backlight Brightness

When opting for high-brightness TFT LCD solutions, increasing the luminance of the backlight system is key. Several proven engineering techniques can help enhance brightness without drastically changing the overall display structure.

4.1. Brightness Enhancement Films (BEF)

BEFs are often integrated into high brightness TFT displays to improve their performance in sunlight readable display applications. They work by redirecting and concentrating light toward the viewer’s direction, effectively increasing perceived brightness without consuming more power.

- Working Principle: BEFs use micro-lens or prism structures to bend and collimate light rays, reducing light diffusion.

- Advantages: No changes are needed to the LED structure or power supply. A simple addition of film boosts brightness by up to 40% in some cases.

- Applications: Widely used in industrial panels and automotive displays that require cost-effective brightness enhancement.

4.2. More LED Light Sources

Another straightforward way to increase backlight brightness is to add more LEDs into the backlight module. With more light-emitting diodes, the panel receives a stronger and more uniform illumination.

- Working Principle: Higher LED count translates directly to more luminous output, improving nits rating of the display.

- Advantages: Reliable and scalable method for brightness increase, often used in large-size industrial displays and outdoor kiosks.

- Challenges: Requires re-design of the backlight frame, thermal management systems, and power supply — increasing cost and complexity.

4.3. Dual-Chip LEDs

In space-constrained designs where adding more LEDs isn’t feasible, manufacturers can use dual-chip LED technology. Each LED contains two light-emitting chips, doubling the brightness output without increasing the number of physical LED units.

- Working Principle: Dual-chip LEDs emit more light from the same footprint, enabling higher brightness within limited space.

- Advantages: Ideal for compact or sealed products where thermal or mechanical limits prevent expanding the backlight module.

- Use Case: Popular in handheld outdoor devices, rugged tablets, and retrofitting existing panel designs for outdoor use.

As part of a high brightness display system, dual-chip LEDs are ideal for compact sunlight readable display designs.

5. Application Scenarios for Sunlight Readable Displays

Sunlight readable displays are essential in a wide range of industries where users interact with screens under direct sunlight or high ambient light environments. Below are some of the most common application fields:

- Outdoor Terminals: Parking meters, self-service ticketing kiosks, parcel lockers, and outdoor ATMs rely on bright, readable displays for user interaction in daylight.

- Industrial Environments: Mining and oilfield control systems often operate in harsh outdoor conditions where display visibility is critical for safety and productivity.

- Medical & Portable Equipment: Handheld diagnostic devices, emergency kits, and mobile ultrasound machines require high brightness for clarity in unpredictable lighting.

- Marine & Navigation: Sunlight-readable screens are essential in boats, ships, and offshore platforms where light reflection from the water can severely reduce visibility.

- Transportation Systems: Passenger information displays, outdoor signage at bus and train stations, and traffic control terminals depend on strong backlighting to remain visible throughout the day.

Among the two main technological approaches — transflective TFT and high brightness backlight — high brightness TFT displays have become increasingly popular in recent years. This is largely due to their cost-effectiveness, stable quality, and long-term availability in the supply chain. Manufacturers and integrators can reuse standard TFT glass structures, which reduces development cost and ensures better scalability. All these use cases demand high performance sunlight readable TFT displays that can operate reliably outdoors.

6. Conclusion: Choosing the Right Solution for Your Project

Choosing the right sunlight readable display or high brightness display solution is no longer a luxury — it’s a core requirement for modern embedded and industrial display systems. Choosing the right solution depends on multiple project factors such as power budget, display size, thickness constraints, cost sensitivity, and environmental durability.

| Solution Type | Advantages | Limitations |

|---|---|---|

| Transflective TFT | Excellent outdoor visibility in strong sunlight; low power consumption; improved readability as ambient light increases. | Lower color saturation; higher manufacturing cost; limited supply availability. |

| High Brightness TFT | Strong brightness (≥ 800 nits); easier to integrate; uses standard TFT glass; cost-effective and mass-production friendly. | Higher power consumption; increased backlight heat; thicker backlight structure. |

For most mainstream industrial and commercial applications, high brightness backlight TFT displays have become the preferred choice. Their ability to deliver excellent daylight readability while maintaining low cost and stable supply chains make them ideal for large-scale projects and product rollouts.

Ultimately, the best approach depends on your specific project needs. If your application prioritizes low power and high readability under sunlight, transflective panels might be suitable. If you need maximum brightness, rapid development, and better cost control, then a high brightness TFT solution is likely your best fit.

We recommend working closely with a professional display manufacturer to evaluate your requirements and deliver a reliable, long-lasting sunlight readable display or high brightness display solution that fits your technical and business needs.

Keyword Spotlight: Sunlight Readable vs High Brightness Displays

Many professionals ask about the difference between sunlight readable displays and high brightness displays. In practice, high brightness displays are often used to achieve sunlight readability by increasing the LED backlight’s intensity. Meanwhile, sunlight readable displays may also include technologies like transflective LCDs or brightness enhancement films. Both terms are frequently used in industrial display selection, and understanding their overlap helps you choose the right display module for your outdoor application.

FAQ: Sunlight Readable & High Brightness Displays

Q1: What is the difference between a sunlight readable display and a high brightness display?

A: A sunlight readable display refers to any display that remains visible under strong ambient light. This includes high brightness displays, which use powerful LED backlights (typically ≥ 800 nits), and transflective LCDs, which reflect ambient light to enhance readability. In short, high brightness displays are one method to achieve sunlight readability, while transflective LCDs offer an alternative low-power solution.

Q2: When should I choose a transflective LCD instead of a high brightness TFT display?

A: Choose a transflective LCD when your project requires low power consumption, especially for battery-powered devices used outdoors. These displays perform better as ambient light increases, making them ideal for rugged, handheld, or sunlight-intensive environments. However, if maximum brightness and vivid color are your priorities, a high brightness TFT display may be a better fit.