In many factories, automation is gradually shifting away from simple PLC-driven control and static HMI pages toward systems that can understand their surroundings, process data locally, and react almost immediately. People usually refer to this change as “AI at the edge” or simply “Edge AI”. Rather than pushing every sensor value or video frame to a remote server, the device its elf has enough compute to run AI models right where the data is generated – on the factory floor, in a plant room, or inside the machine.

Behind this shift are newer SoCs that put CPU, GPU, and an NPU (Neural Processing Unit) onto the same die. The Rockchip RK3576 is one of these new-generation processors. Once RK3576 is placed on an industrial SBC and combined with a solid TFT display module, you basically have a ready-made hardware platform for the next generation of control panels: all the usual HMI features plus room for Edge AI.

1. RK3576 as the Core of an AI Edge HMI Platform

Rockchip’s RK3576 is an ARM-based application processor aimed at fairly demanding embedded use cases.

It combines:

- Multi-core CPU cluster that takes care of the OS and control logic.

- Graphics engine that can handle smooth 2D/3D user interfaces.

- Built-in NPU with a few TOPS of AI compute (around 6 TOPS in typical configs) for running inference workloads.

- Plenty of I/O for cameras, networking, storage, and various fieldbus connections.

In a traditional industrial control panel, the SoC might be selected mainly for CPU performance and display support. With RK3576 on board, the panel is no longer just a screen. The NPU gives it enough headroom to run computer vision, anomaly detection, or basic on-device voice recognition without depending on a remote server.

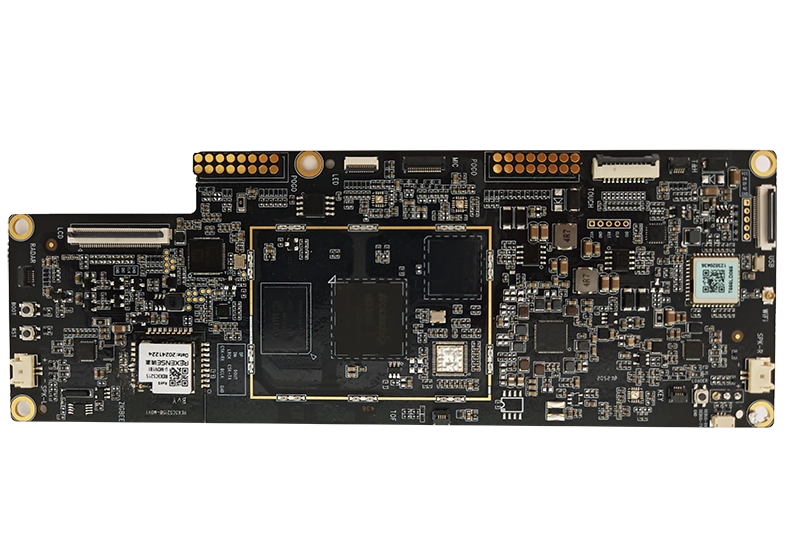

2. From SBC to Complete Panel: Rocktech’s Hardware Building Blocks

To make this useful in a real control panel, the SoC has to sit on a stable, industrial-grade platform instead of a one-off demo board. This is typically where many projects slow down, especially around display timing, power sequencing, thermal design, and long-term component availability. By combining:

- An RK3576-based SBC with NPU acceleration, industrial interfaces, and OS support (Android or Linux).

- Industrial TFT or IPS displays with appropriate resolution, brightness, and viewing angle.

- Optional capacitive touch panels and custom cover glass for front-panel integration.

In this setup, Rocktech can supply the hardware base for OEMs and system integrators who want to move toward AI-enabled HMIs without starting the whole design from zero. In practice, the SBC runs the main software, the NPU takes over the heavy AI inference, and the display/touch stack is simply the part the operator sees and touches.

3. Why Edge AI Matters in Industrial Control Panels

For a long time, most industrial panels were basically used to show live values, alarms, and a few configuration screens.

Once you add Edge AI, the same panel can do a lot more:

- On-device vision: connect one or more cameras to the panel and it can spot defects, track whether someone is inside a hazardous area, or check basic product orientation without pushing the video stream to the cloud.

- Predictive maintenance: Local AI models can analyze vibration, motor current, or temperature patterns and alert operators before a failure occurs.

- Human-centric interaction: The panel can recognize operators, adjust screens based on roles, and support simple voice commands or gestures.

- Local decision making: In environments with unreliable networks or strict data privacy rules, decisions must be taken locally, not in a remote data center.

All of these use cases rely on strong compute and low latency. A CPU alone can struggle with real-time inference, especially if it must also handle UI, communication stacks, and fieldbus protocols. On RK3576, most of the neural network work can move to the NPU. That way the main CPU is free enough to keep the UI snappy and the control logic predictable, even when AI tasks are running in the background.

4. Typical System Architecture Based on RK3576

A typical RK3576-based industrial panel with Edge AI support might be put together like this:

- SoC: Rockchip RK3576, handling OS, control logic, and AI inference via NPU.

- SBC: Rocktech RK3576 SBC providing DDR, eMMC or SSD, Ethernet, USB, CAN, RS-485/RS-232, and digital I/O.

- Display module: Rocktech TFT/IPS panel (for example 7″, 10.1″, or other sizes) with LVDS, MIPI-DSI, or RGB interface.

- Touch and cover glass: Projected capacitive touch (PCAP) with custom cover lens and front glass, designed for harsh industrial environments.

- Peripherals: Cameras (via MIPI CSI or USB), microphones, sensors, and field actuators.

- Operating system: usually Android or some flavor of embedded Linux, depending on how the HMI is built and what software stack the customer prefers.

In this architecture, the NPU is typically accessed through a vendor-provided SDK or AI runtime. AI models are trained in the cloud (for example using TensorFlow, PyTorch, or ONNX workflows) and then converted into an optimized format that can run efficiently on the RK3576 NPU. In many projects, model conversion and performance tuning take more time than the initial model training itself, especially when balancing accuracy, latency, and thermal limits on the target hardware.

5. Example AI Edge Use Cases for RK3576-Based Panels

5.1 Visual Quality Inspection at the Machine

Rather than streaming every high-resolution frame to a server, a Rocktech RK3576 panel can plug in a local camera and run a detection or classification model right on the NPU. The panel can:

- Detect surface defects on parts in real time.

- Verify that labels are present and readable.

- Flag out-of-spec products immediately to the operator.

The operator sees results, statistics, and live video on the integrated display, and the machine can react within milliseconds without network latency.

5.2 Operator Identification and Access Control

With a front-facing camera and a moderate AI model running on the NPU, the control panel can:

- Recognize authorized operators.

- Switch interface language or layout based on user profile.

- Restrict access to certain configuration screens.

That way you rely less on separate badge readers or extra terminals, and the overall operation becomes easier for users – especially in plants where several languages are used side by side.

5.3 Local Anomaly Detection and Condition Monitoring

If the panel continuously logs vibration, current, or other sensor signals and feeds them into an AI model, the RK3576-based system can flag patterns that usually show up before a failure. Instead of only showing alarms after the fact, the HMI becomes a predictive maintenance assistant.

5.4 Smart Building and Energy Panels

In building automation or energy management, Rocktech’s SBC + display platform can host AI models that:

- Optimize HVAC settings based on occupancy and historical behavior.

- Classify power usage patterns and detect abnormal consumption.

- Integrate vision (occupancy) and environmental sensors into one unified control interface.

6. Benefits of Choosing a Pre-Integrated Hardware Platform

You can, of course, build a system from separate boards, displays, and an external AI accelerator, but in practice that tends to add both risk and development time. A pre-integrated solution, such as Rocktech’s combination of:

- RK3576-based SBC with NPU and industrial I/O,

- industrial-grade TFT display modules,

- PCAP touch and customized cover glass,

offers several concrete advantages:

- Shorter time-to-market: Shorter time-to-market: the main hardware pieces – SBC, display, and signal timings – are already matched and validated.

- Lower project risk: Fewer unknowns in signal integrity, power sequencing, and display timing.

- Consistent supply chain: One partner provides both the main computing module and the display front-end.

- Scalability: The same platform can be reused for different panel sizes or enclosures while keeping the AI and control logic unchanged.

For customers who want to add AI Edge features later, starting with RK3576 means the NPU is already there, even if the first software release only uses CPU-based control and visualization. When the AI application is ready, the same hardware can be updated by firmware or software changes, without redesigning the electronics.

7. Designing for the Future of Industrial HMI

Even if your current customers are not asking for Edge AI yet, it is quite likely that the next generation of machines and smart building systems will expect more local intelligence rather than relying only on the cloud. Selecting a hardware platform that combines:

- A capable SoC like RK3576 with integrated NPU,

- an industrial-grade SBC with the right interfaces,

- and a robust TFT display/touch stack,

ensures that your control panels are ready for that evolution. So the panel is no longer just a “dumb” screen hanging off a PLC. It can act as a local AI node, a data hub, and a capable user interface in the same enclosure.

8. Conclusion

RK3576 combines solid CPU performance, decent graphics, and on-chip NPU acceleration, which makes it a very practical base for Edge AI functions in industrial control panels. When integrated into a Rocktech SBC and combined with industrial TFT display modules and touch solutions, it forms a complete hardware platform for next-generation HMIs.

For OEMs and system integrators, this means they can start adding AI-enabled features – vision, anomaly detection, smarter interaction – without redesigning the whole hardware platform from scratch. A single board and display solution, built around RK3576, provides the compute power, connectivity, and display quality needed to bring Edge AI into real industrial environments.

Frequently Asked Questions (FAQ)

What is Edge AI in industrial control panels?

Edge AI refers to running artificial intelligence models directly on local devices at the edge of the network,such as industrial control panels, instead of relying on remote cloud servers. In industrial environments, this enables real-time decision making, lower latency, improved data security, and continued operation even when network connectivity is unstable or unavailable.

Why is the RK3576 suitable for AI Edge applications?

The Rockchip RK3576 integrates CPU, GPU, and a dedicated Neural Processing Unit (NPU) on a single chip. The NPU provides hardware acceleration for AI workloads, allowing tasks like image recognition, anomaly detection, and smart analysis to run efficiently alongside traditional HMI functions without overloading the main CPU.

Can AI applications run locally without cloud connectivity?

Yes. One of the main advantages of Edge AI is that AI models run locally on the device. Using the RK3576 NPU, industrial control panels can perform inference in real time without sending data to external servers, which is critical in scenarios with strict security policies or limited internet access.

What AI use cases are realistic for RK3576-based control panels?

Typical applications include visual inspection, operator recognition, anomaly detection in machine behavior, predictive maintenance, and intelligent energy management in automation systems. These functions can be integrated directly into industrial HMIs using the RK3576’s AI acceleration capabilities.

Why combine an SBC with an industrial TFT display?

A control panel is not only a computing device but also a human interface. Combining an RK3576-based Android SBC with an industrial-grade TFT or IPS display ensures both strong AI processing capability and a reliable, high-quality visual interface. This integration simplifies development and improves overall system stability.

Is RK3576 suitable even if AI is not used in the first version?

Yes. Even if your current project does not immediately use AI features, choosing an RK3576 platform provides future scalability. The built-in NPU ensures that AI functions can be enabled later through software updates without redesigning the hardware.