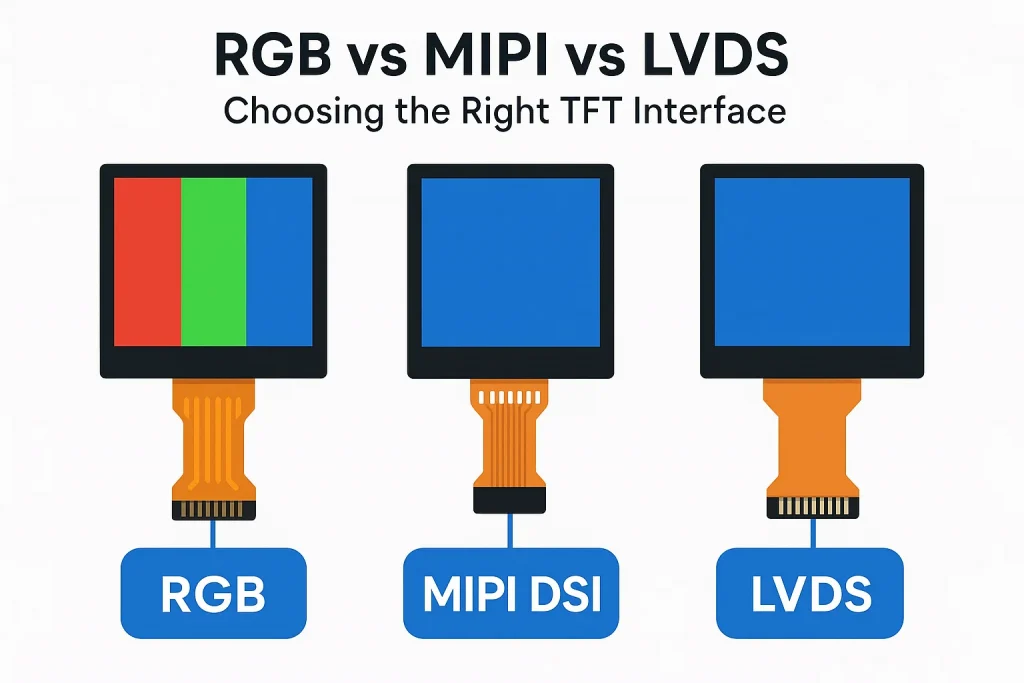

RGB vs MIPI vs LVDS: Choosing the Right TFT Interface

When it comes to designing with TFT LCD modules—whether for embedded systems, industrial equipment displays, IoT devices, or smart home appliances—one of the most critical steps is selecting the right TFT display interface. The choice between RGB interface, MIPI DSI display connection, and LVDS LCD interface will directly affect your project’s performance, cost, and power efficiency.

Each interface type offers unique advantages:

RGB is often preferred for small-size TFT LCDs and simpler designs, MIPI DSI suits high-resolution LCD modules in compact devices, while LVDS is ideal for wide-viewing-angle display

anels used in industrial LCD screens. Choosing the wrong interface could result in higher manufacturing costs, slower data transfer, or excessive power consumption, especially in low-power LCD screens for IoT applications.

In this guide, we’ll explain how each TFT LCD interface type works, compare their pros and cons, and provide practical tips for selecting the best custom LCD solution for your application.

Introduction to TFT Interfaces

What is a TFT Display?

A TFT display is a type of LCD module that uses thin-film transistor technology to improve image quality, including color accuracy, contrast ratio, and refresh rates. These displays are widely used in smartphones, industrial machines, medical-grade LCD monitors, and automotive dashboards. For applications needing wide viewing angle LCD panels or low power LCD screens for IoT devices, TFT technology offers both flexibility and performance.

Why the Interface Matters in TFT Displays

The TFT LCD interface is the communication pathway between the display module and the device’s main processor. It determines:

-

How fast pixel data is transferred (impacting resolution and frame rate)

-

How much power the system consumes

-

How complex the design and manufacturing process will be

Without the right interface, even a high resolution TFT LCD module can underperform.

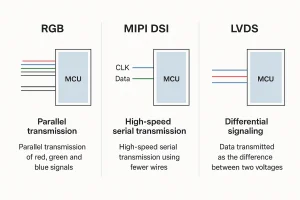

Understanding the RGB Interface in TFT LCD Displays

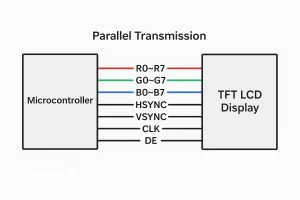

How the RGB Interface Works

The RGB interface is one of the most common ways to connect a TFT LCD display to a microcontroller or processor. It transmits pixel data in parallel form, where each pixel’s red, green, and blue signals are sent simultaneously. This direct transmission method eliminates the need for complex data encoding, making it especially popular in embedded systems, industrial displays, and smart home devices that require straightforward integration.

Advantages of the RGB Interface

-

Simplicity – The RGB interface is easy to implement, making it suitable for low-cost embedded designs and microcontroller-based display solutions.

-

Low Latency – Since the data is transmitted directly, there is minimal delay, ensuring smooth screen updates for real-time display applications such as medical monitoring devices and industrial equipment.

-

Broad Compatibility – Many older MCUs, development boards, and industrial control systems support RGB displays, which makes it a reliable choice for long-term projects.

This makes the RGB interface an excellent option for projects where cost efficiency, fast response, and compatibility with existing hardware are key considerations.

Limitations of the RGB Interface

-

High Pin Count – The interface requires multiple parallel data lines (often 18-bit or 24-bit), which increases connector size and PCB complexity.

-

Limited Speed – While fine for QVGA or WVGA resolutions, RGB struggles with high-resolution, high-refresh-rate TFT LCD displays used in modern consumer electronics.

-

Short Transmission Distance – RGB signals are not designed for long cable runs, and signal degradation becomes an issue over distance, making it less ideal for large-format displays or remote display modules.

Exploring the MIPI DSI Interface in TFT LCD Displays

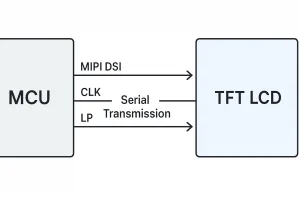

How MIPI DSI Works

MIPI DSI (Mobile Industry Processor Interface – Display Serial Interface) is a widely adopted high-speed serial interface designed primarily for mobile devices, tablets, automotive displays, and embedded systems. Unlike traditional RGB parallel interfaces, MIPI DSI transmits pixel data using fewer wires at very high speeds. This makes it especially suitable for modern TFT LCD displays that require slim connectors, lower power usage, and support for high-resolution graphics.

Benefits of MIPI DSI

-

High Data Rates – MIPI DSI supports extremely fast data transfer, enabling high-resolution TFT LCD panels up to 4K and beyond, making it ideal for smartphones, automotive clusters, and advanced embedded devices.

-

Low Power Consumption – With efficient data encoding, it reduces power usage, which is critical in battery-powered devices such as smartwatches, handheld medical instruments, and IoT displays.

-

Compact Design – By using fewer pins and smaller connectors compared to RGB or LVDS, MIPI DSI allows for slimmer device designs and simplified PCB layouts, which is crucial for wearables, smart home devices, and compact consumer electronics.

These advantages position MIPI DSI as the preferred choice for manufacturers seeking a balance of performance, power efficiency, and compact design in their display applications.

Drawbacks of MIPI DSI

-

Complex Implementation – MIPI DSI requires specialized hardware, compatible processors, and dedicated driver support, which can increase development complexity.

-

Short Cable Lengths – The interface is best suited for short-distance transmission, making it less practical for remote or large-format displays.

-

Limited in Some Industrial Applications – Compared with LVDS (Low-Voltage Differential Signaling), MIPI DSI is more vulnerable to electrical noise, which can be a drawback in industrial environments or rugged outdoor displays.

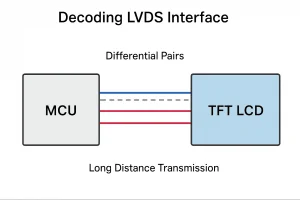

Decoding the LVDS Interface in TFT LCD Displays

How LVDS Works

LVDS (Low-Voltage Differential Signaling) is a widely used interface for TFT LCD displays in industrial monitors, automotive displays, and medical equipment. It works by transmitting pixel data through differential pairs, which significantly reduce electromagnetic interference (EMI) and allow for high-speed, long-distance transmission with minimal signal loss. Because of its robustness and reliability, LVDS remains one of the most popular choices for large-format and high-resolution display applications.

Pros of the LVDS Interface

-

Excellent Noise Immunity – LVDS performs reliably in electrically noisy environments, making it ideal for industrial control systems, factory automation, and medical devices where display stability is critical.

-

High Bandwidth – With the ability to handle high-resolution TFT LCD panels (Full HD, WUXGA, and beyond), LVDS is well-suited for industrial monitors, automotive dashboards, and professional-grade displays.

-

Long Cable Support – Unlike MIPI DSI or RGB interfaces, LVDS supports long-distance transmission up to several meters, which is essential for large machines, outdoor signage, and distributed display systems.

These strengths make LVDS a go-to solution for engineers who need a balance of stability, bandwidth, and distance support in demanding environments.

Cons of the LVDS Interface

-

Higher Power Consumption than MIPI – LVDS consumes more power compared with MIPI DSI, making it less efficient for battery-powered devices such as wearables or handheld instruments.

-

More Complex Connectors Compared to RGB – The cabling and connectors required for LVDS are bulkier and more complex, which increases PCB design complexity and assembly costs.

-

Costlier Implementation for Small Devices – For compact electronics like smart home devices or IoT displays, LVDS may not be the most cost-effective solution due to its connector size and design requirements.

Key Technical Differences Between RGB, MIPI, and LVDS

| Parameter | RGB Interface | MIPI DSI Interface | LVDS Interface |

| Signal Transmission | Parallel transmission; separate lines for R, G, B and sync signals | High-speed serial transmission using differential lanes | Differential signaling with paired lines, minimizing EMI and noise |

| Data Transfer Speed | Limited by clock frequency; best for low to mid resolutions (QVGA–WVGA) | Supports very high resolutions (Full HD, 4K) with high refresh rates | Handles high resolutions reliably; ideal for large industrial and automotive displays |

| Power Consumption | Higher power usage due to multiple active lines | Lowest power consumption; optimized for portable and battery-powered devices | Moderate power; higher than MIPI but lower than legacy parallel systems |

| Key Advantages | Simple design, broad MCU compatibility | High bandwidth, low power, compact design | Excellent noise immunity, long-distance, robust for industrial environments |

| Limitations | Not suitable for high-resolution or long-distance applications | Requires specialized hardware and driver support | Higher cost and complexity for small devices |

| Recommended Applications | Entry-level embedded systems, cost-sensitive designs, educational projects | Smartphones, tablets, smartwatches, automotive infotainment, smart home devices | Industrial monitors, medical devices, automotive clusters, outdoor signage |

Choosing the Right TFT LCD Interface for Your Application

Best TFT Interface for Low-Power, Compact Devices

MIPI DSI Interface — Widely regarded as the preferred choice for smartphones, smartwatches, wearable devices, handheld medical equipment, and IoT TFT LCD modules.

Key advantages include:

-

Low power consumption, ideal for battery-operated devices

-

High-speed data transmission for smooth graphics and touch responsiveness

-

Compact connector design, saving space in slim form factors

-

Perfect for high-resolution small-to-medium TFT LCD displays

MIPI DSI continues to gain traction in automotive digital dashboards, smart appliances, and advanced IoT solutions, where space and energy efficiency are essential.

Best TFT Interface for High-Resolution Large Displays

LVDS Interface — The go-to solution for industrial control panels, automotive infotainment systems, medical-grade monitors, and large-format TFT LCD displays.

Key advantages include:

-

Long-distance signal transmission without image degradation

-

High bandwidth support, suitable for high-resolution applications

-

Excellent noise immunity, making it reliable in harsh industrial environments

-

Supports professional-grade, large-size TFT LCD panels for industrial and medical applications

LVDS remains dominant in industrial automation, factory displays, and large-screen medical devices, where durability and signal stability are non-negotiable.

Best TFT Interface for Simple, Cost-Sensitive Projects

RGB Parallel Interface — A budget-friendly solution for embedded systems, smart home appliances, thermostats, and custom control panels.

Key advantages include:

-

Low implementation cost, easy to integrate into existing designs

-

Works well for low-to-mid resolution TFT LCDs

-

Suitable for legacy systems and embedded projects where simplicity and affordability are priorities

RGB interfaces remain relevant for low-cost IoT devices, basic display upgrades, and embedded electronics projects, providing a reliable yet economical option.

For engineers working with MCU-based designs, RGB and similar MCU-driven TFT modules are widely used in cost-sensitive embedded projects due to their simple integration and broad microcontroller compatibility. You can explore example MCU-driven TFT modules here: MCU TFT Display Examples.

Industry Trends & Future of TFT LCD Interfaces

-

MIPI DSI is rapidly expanding in smart automotive dashboards, wearable devices, and IoT-enabled displays, driven by demand for high-resolution, compact, and low-power solutions.

-

LVDS continues to dominate industrial, medical, and professional display markets, where signal integrity over long distances is critical.

-

RGB interfaces maintain a strong presence in cost-sensitive embedded systems and retrofit display upgrades, offering simplicity and affordability.

Conclusion: Choosing the Right TFT LCD Interface

Selecting between RGB, MIPI DSI, and LVDS requires balancing:

-

Resolution requirements

-

Power consumption

-

Project budget

-

Design complexity

Guidelines:

-

Choose RGB for low-cost, small-to-medium TFT LCDs

-

Opt for MIPI DSI for high-resolution, compact, battery-powered devices

-

Select LVDS for large industrial or medical panels requiring long cable runs and high noise immunity

A well-chosen TFT LCD interface ensures your display delivers crisp image quality, reliable performance, and energy-efficient operation, enhancing your product’s competitiveness in both consumer electronics and industrial markets.