Optical bonding is a critical step in producing high-performance displays, especially for industrial, automotive, and outdoor applications. Two popular methods dominate the market: OCA (Optically Clear Adhesive) and OCR (Optically Clear Resin). While both aim to improve visual clarity, durability, and sunlight readability, they differ significantly in material form, application process, and suitability for different designs. This article compares OCA and OCR to help you make the right choice for your project.

1. What Is OCA?

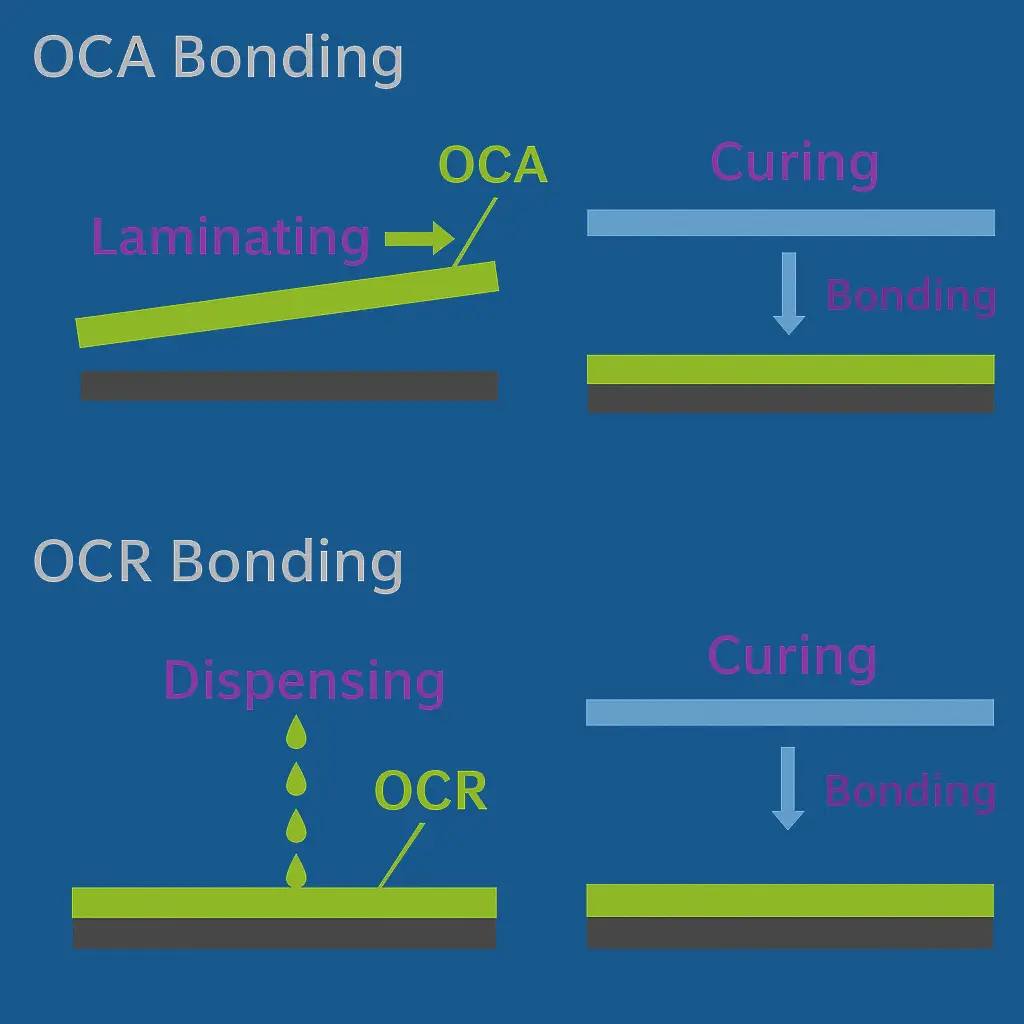

OCA is a solid, film-based adhesive with high optical transparency. It comes in pre-cut sheets or rolls and is applied between the cover glass (or touch sensor) and the display module. Since it is a dry film, OCA bonding is a fast process suitable for flat-panel designs with uniform gap thickness.

2. What Is OCR?

OCR is a liquid, UV- or thermal-curable adhesive designed to fill gaps between display layers. It flows into irregular or non-uniform gaps and is ideal for bonding curved or stepped glass to display modules. OCR requires dispensing and curing, making it more process-intensive but more flexible in complex geometries.

3. Key Differences Between OCA and OCR

| Criteria | OCA (Film) | OCR (Liquid) |

|---|---|---|

| Material form | Solid adhesive film | Liquid resin |

| Gap filling | Best for flat, uniform gaps | Excellent for uneven or curved surfaces |

| Process speed | Fast (no curing) | Slower (requires curing) |

| Reworkability | Possible before lamination is complete | Very difficult after curing |

| Equipment cost | Lower (lamination press) | Higher (dispensing + curing systems) |

| Application scale | High-volume, standardized panels | Specialized or premium designs |

4. When to Choose OCA

- Flat-panel displays with consistent bonding gaps.

- High-speed mass production lines.

- Cost-sensitive projects where rework flexibility is important.

- Applications where maximum throughput is required.

5. When to Choose OCR

- Curved cover glass or complex display shapes.

- Designs with non-uniform gaps or deep steps.

- Premium devices requiring superior gap filling and optical performance.

- Applications demanding enhanced vibration and impact resistance.

6. Performance Comparison

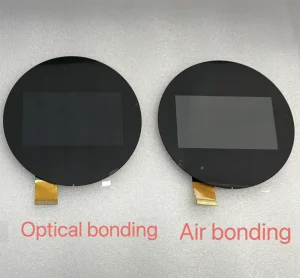

Both OCA and OCR improve sunlight readability by eliminating internal reflections caused by air gaps. However, OCR offers slightly better optical performance in non-uniform designs because it fully fills micro-voids. OCA, on the other hand, offers faster processing speed and simpler rework, making it a better fit for high-volume production of standard panels.

7. Cost Considerations

OCA typically offers lower total production costs due to faster processing and simpler equipment. OCR involves higher capital investment and longer process cycles, but may reduce defects in complex assemblies, resulting in long-term cost benefits for premium products.

8. Final Decision Guide

If your project involves large-scale, flat display production, OCA is likely the better choice for efficiency and cost control. If you are building a high-end product with curved or irregular glass, OCR will deliver better visual quality and durability, despite higher production complexity.

Partner With a Professional Optical Bonding Manufacturer

Choosing between OCA and OCR requires understanding both the design requirements and production capabilities. A qualified optical bonding provider can evaluate your project and recommend the best method for your needs.