Selecting the optimal Marine Grade TFT represents one of the most crucial engineering decisions impacting marine electronic performance and reliability.

From advanced fish finders to sophisticated navigation systems, modern marine displays serve as the primary interface between complex data and the user. For design engineers working in the maritime sector, these five essential specifications ensure exceptional performance in challenging marine environments.

According to research from Boating Industry, the demand for high-performance marine displays has grown by 34% over the past two years, driven by advancements in marine technology.

Marine Grade TFT: Superior Brightness for Sunlight Visibility

Q: What makes high-intensity illumination essential for marine display applications?

A: The marine environment presents extreme lighting challenges where standard displays become unreadable. An effective Marine Grade TFT requires minimum 800 nits brightness, with premium marine applications demanding 1000 nits. This high luminosity must be combined with advanced anti-reflective coatings and optical treatments to maintain clarity in direct sunlight conditions.

Modern fishing equipment utilizes these technologies to ensure anglers can accurately interpret sonar data and navigation charts without visual compromise.

The combination of high-intensity backlighting and specialized optical enhancements enables immediate decision-making based on clear visual information, even in challenging tropical conditions where sunlight intensity exceeds 100,000 lux.

For detailed technical specifications, see our custom solutions.

Sunlight Readable TFT Display: Advanced Waterproof Touch Interface

Marine displays demand exceptional protection against water intrusion and environmental hazards:

- A reliable Sunlight Readable TFT Display requires IP65 certification or higher, ensuring complete protection against dust and temporary immersion up to 1 meter for 30 minutes. This protection level is critical for radar and autopilot interfaces constantly exposed to sea spray and humidity.

The implementation of projected capacitive touch technology ensures stable performance even with water droplets present on the screen surface:

- Modern solutions maintain touch accuracy within ±1.5mm while supporting glove operation and wet hand tracking, essential features for marine applications where operators need to interact with displays in various weather conditions.

As noted by Marine Electronics Journal, the latest waterproof touch technologies maintain consistent performance even in sustained salt spray environments, ensuring long-term reliability for commercial marine applications.

Optical Bonding for Outdoor Displays: Enhanced Durability and Clarity

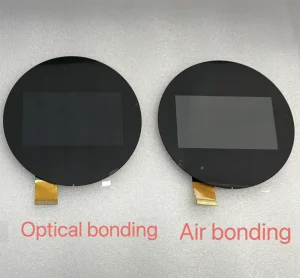

Q: How does optical bonding technology address marine environment challenges?

A: Optical Bonding for Outdoor Displays solves three critical marine display issues through advanced lamination technology.

- First, it eliminates the air gap between layers, reducing internal reflections by up to 40% and significantly enhancing sunlight readability.

- Second, the bonding resin prevents condensation formation that typically occurs in humid marine environments.

- Third, the structural integrity provided by optical bonding improves resistance to shock and vibration from marine engines and rough sea conditions.

The bonding process uses high-transmittance optical cement with UV stability, ensuring long-term performance without yellowing or degradation. This technology enables displays to maintain >1000:1 contrast ratio even in direct sunlight, while providing additional mechanical strength that reduces the risk of glass breakage from impact or vibration.

Waterproof Touchscreen Marine: Extended Temperature Performance

Marine electronics must operate reliably across extreme temperature ranges from -30°C to 80°C while maintaining full functionality.A quality Waterproof Touchscreen Marine solution incorporates wide-temperature liquid crystals, industrial-grade components, and thermal management systems to ensure stable performance in arctic cold and tropical heat.

The display system utilizes low-temperature polycrystalline silicon (LTPS) technology that maintains fast response times across the entire temperature range.

Additionally, specialized heating elements can be integrated for operation in sub-zero conditions, while thermal diffusion layers prevent overheating in high-temperature environments. These features are complemented by salt spray resistance coatings that protect against corrosion in saltwater environments, extending the display’s operational life in marine applications.

High Brightness TFT: Impact Resistance for Portable Marine Applications

Portable fishing equipment requires High Brightness TFT that combine optical performance with mechanical durability:

- For kayak-mounted units and portable fish finders, displays must meet IK08-IK10 impact resistance ratings while maintaining 1000+ nits brightness in compact form factors.These solutions incorporate chemically strengthened glass (such as Gorilla Glass or Dragontrail) with surface compression exceeding 800 MPa, providing exceptional scratch and impact resistance.

- The mechanical design includes reinforced mounting points, shock-absorbing materials, and balanced weight distribution to withstand the constant vibration and potential impacts encountered in small watercraft operations.

- Additionally, these displays feature optimized power management systems that enable extended battery life while maintaining high brightness levels essential for daylight visibility.

| Parameter | Standard Grade | Premium Grade |

|---|---|---|

| Luminance | 140-700 nits | 800-1000 nits |

| Ingress Protection | IP65 | IP67-IP69K |

| Operating Temperature | -20°C to 70°C | -30°C to 80°C |

| Impact Resistance | IK06 | IK08-IK10 |

| Optical Enhancement

(optional: +AG ,+AR etc.) |

Air bonding | Optical Bonding |