I2C vs USB in Display Technology: An Overview

When developing a projected capacitive (PCAP) touch screen product, selecting the right communication interface is crucial. Among the many options available, I2C vs USB remains one of the most common comparisons. Both technologies serve as communication bridges between the touch controller and the host device, but their design goals and performance differ significantly.

-

I2C for LCD display is widely used in embedded systems, where cost, simplicity, and low power consumption are priorities.

-

USB Display, on the other hand, dominates in consumer electronics and industrial devices where higher bandwidth and user-friendly connectivity are essential.

Understanding these two approaches helps product designers optimize performance, cost, and user experience.

Introduction to I2C for LCD Display Communication

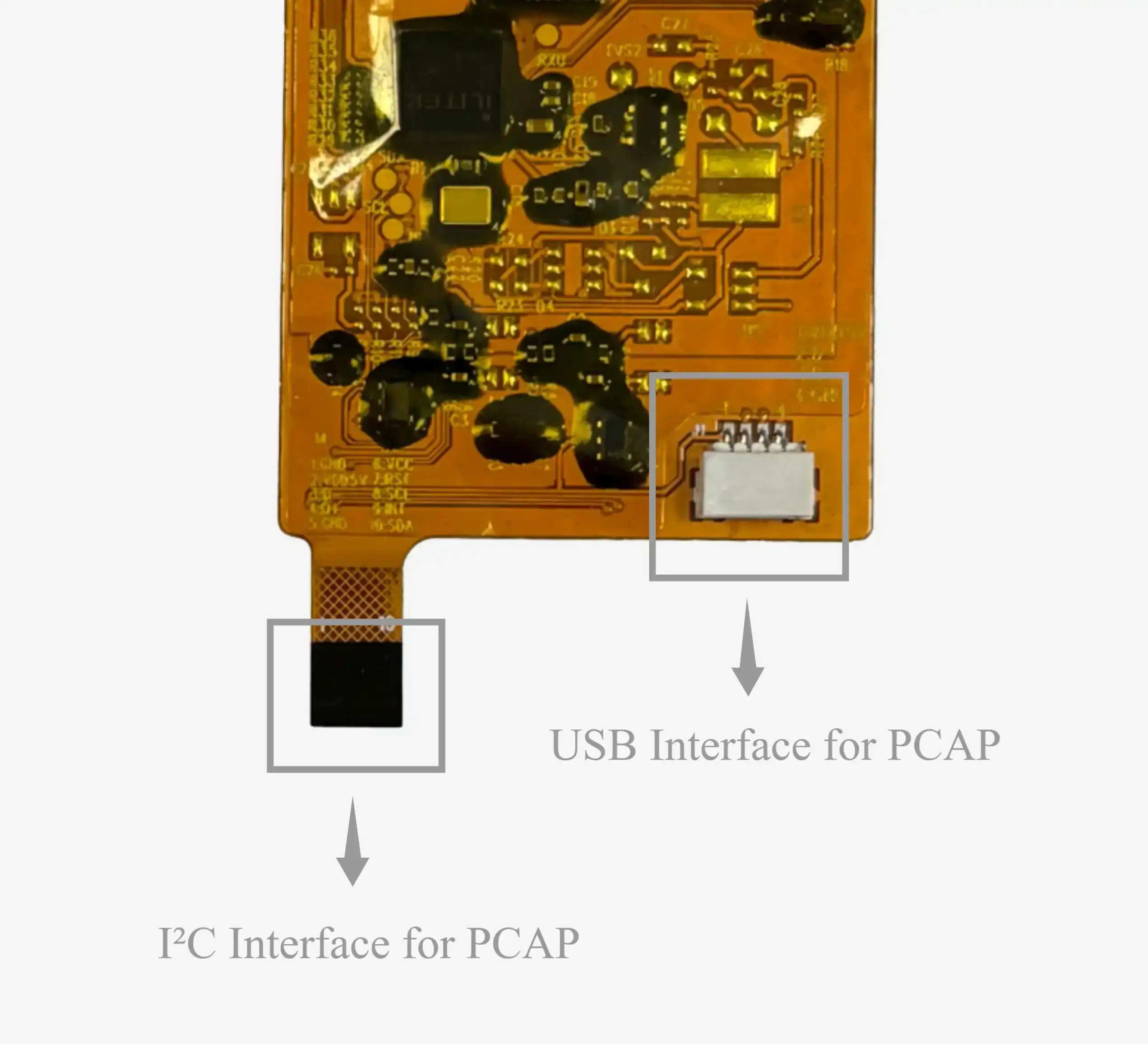

The Inter-Integrated Circuit (I2C) protocol is a simple serial interface that uses only two lines—SDA (data) and SCL (clock)—to transmit control or touch data. It is easy to implement on printed circuit boards (PCBs) and is especially suitable for compact, low-cost embedded designs.

How USB Touch Interfaces Operate

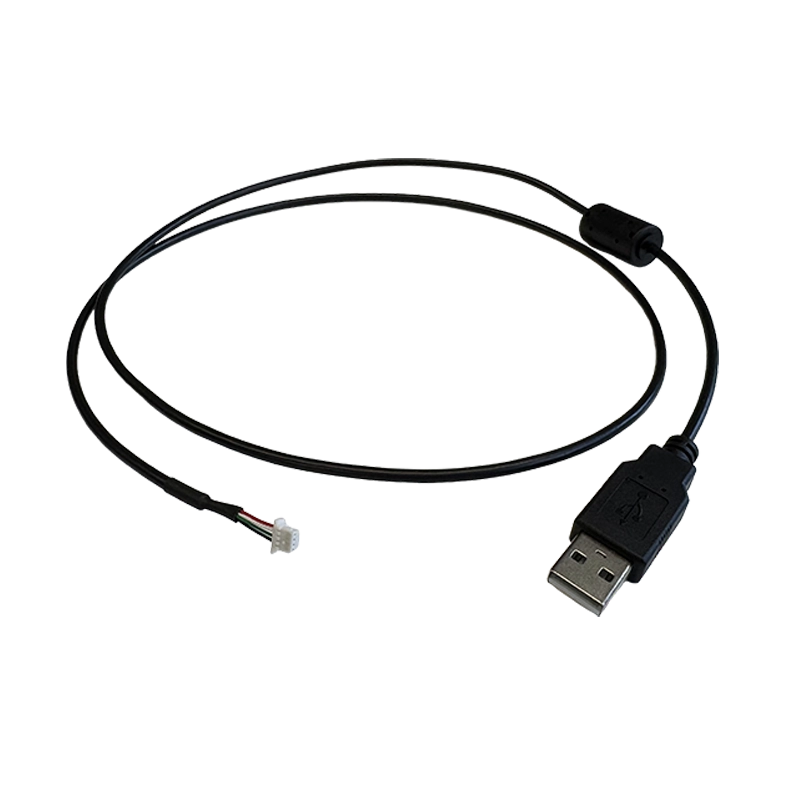

USB interfaces follow a host–device structure. With native driver support and plug-and-play capability, they can be recognized instantly by major operating systems such as Windows, Linux, and Android, making USB a convenient option for touch display applications.

Why Comparing I2C vs USB Matters for PCAP Touch Panels

Since PCAP panels are used in applications ranging from handheld embedded systems to desktop monitors, knowing the trade-offs between I2C and USB ensures the right balance between integration complexity and user functionality.

Strengths of I2C for LCD Display Integration

Simplified Hardware and Cost Advantages

I2C-based touch displays require minimal hardware resources. With only two signal lines—SDA and SCL—they significantly reduce pin count and PCB complexity. This simplicity not only eases circuit design but also lowers production costs, making I2C an attractive choice for cost-sensitive projects and compact embedded systems.

Power Efficiency in I2C Liquid Crystal Displays Applications

Devices powered by batteries or energy-constrained systems greatly benefit from I2C’s low power consumption. As a result, I2C liquid crystal touch modules are widely used in handheld terminals, e-bikes, portable medical devices, and other applications where extending battery life is critical.

Where I2C Works Best in Embedded Systems

I2C is most effective for small- to medium-sized touch panels integrated directly on a system board. It excels in scenarios with short communication distances and moderate data throughput requirements, offering reliable performance while keeping hardware and software design simple.

Advantages of USB Touch Display in Modern Devices

Faster Data Transfer for Multi-Touch Signals

USB display connections support higher data bandwidth, enabling smooth multi-touch gestures, pinch-to-zoom, and fast response times. This capability is especially important for larger PCAP panels with higher resolutions, where quick and accurate touch recognition is essential.

Plug-and-Play Benefits of USB Touch Technology

Unlike I2C, USB touch interfaces offer broad compatibility. Standardized HID drivers allow devices to be instantly recognized across multiple operating systems, including Windows, Linux, and Android, minimizing integration effort and reducing development time.

Typical Use Cases for USB Display in Consumer and Industrial Products

USB-based solutions are commonly found in monitors, point-of-sale (POS) terminals, and human-machine interfaces (HMI). The convenience of transmitting both power and data through a single cable makes USB an ideal choice for consumer devices and industrial equipment where simplicity and user-friendliness are important.

I2C vs USB: Technical and Practical Differences

To better understand the differences, the following table highlights the main contrasts between I2C vs USB in PCAP touch applications:

| Feature | I2C for LCD Display | USB Display / USB Touch |

|---|---|---|

| Data Rate | 100 kbps – 3.4 Mbps (limited) | 1.5 Mbps – 40 Gbps (USB 1.1 to USB 3.x) |

| Distance | Short (on-board, a few centimeters) | Long (up to several meters with cables) |

| Hardware | Simple (two-wire interface) | Complex (requires PHY, cable, driver support) |

| Cost | Low | Higher |

| Power | Low consumption | Higher consumption |

| Multi-Touch | Limited for large data sets | Fully supported with smooth performance |

| Plug-and-Play | Not available | Supported across OS platforms |

| Best Use Cases | Embedded systems, small LCDs | Monitors, POS, industrial HMI |

1. Data Transmission Speed and Bandwidth

I2C is sufficient for simple touch data but not for high-speed requirements. USB provides ample bandwidth for complex gestures.

2. Connectivity Range and Cable Length Limits

I2C works reliably only over short traces. USB, however, supports long cables, making it ideal for peripheral displays.

3. Hardware Complexity and Software Stack

I2C requires minimal logic in microcontrollers. USB demands protocol stacks and operating system drivers, but offers broader compatibility.

4. Multi-Touch Capability and Performance

Large multi-touch displays are better handled with USB. I2C may lag when multiple touch points need to be processed simultaneously.

5. Power Consumption and System Efficiency

Power-sensitive designs benefit from I2C. High-performance devices favor USB despite its higher power draw.

Making the Right Choice: I2C vs USB for PCAP Touch Screens

When to Select I2C for LCD Display Projects

-

Choose I2C for LCD display for small-to-medium screens (typically under 10 inches).

-

Ensure the touch IC supports multi-touch efficiently if your application needs multiple touch points.

-

I2C is ideal for embedded devices with low power budgets and cost constraints.

When USB Touch or USB Display Is the Better Option

-

Select USB touch for larger displays (10 inches and above) where data rate and multi-touch responsiveness are critical.

-

USB is preferred if the touch controller IC is designed for USB HID and the device requires plug-and-play functionality.

Hybrid Approaches Combining I2C and USB

-

Some devices use I2C internally between the touch IC and main board, and USB externally for end-user interfaces.

-

This approach is useful when screen size is moderate, internal communication is simple, and external connectivity must remain versatile.

Key Considerations: Cost, Speed, IC, and Screen Size

-

Screen size, touch controller IC capabilities, power, cost, and desired user experience are all crucial in deciding between I2C vs USB.

-

Small, simple panels → I2C + compatible IC

-

Large, high-resolution panels → USB + high-performance touch IC

Conclusion

Both I2C liquid crystal display solutions and USB Display/USB Touch technologies play critical roles in PCAP touch screen applications. I2C offers a lightweight, power-efficient interface for embedded systems, while USB provides speed, compatibility, and ease of use for consumer and industrial devices.

By understanding the strengths and trade-offs of I2C vs USB, product developers can make informed decisions that align with technical requirements and market expectations.

At Rocktech, we specialize in providing high-quality TFT LCD with PCAP touch screens, including I2C and USB display solutions for a wide range of applications, from embedded systems to industrial HMIs. Our expertise ensures that you get the optimal interface solution for your product’s performance and user experience needs.