The Problem with Air Gaps in Display Modules

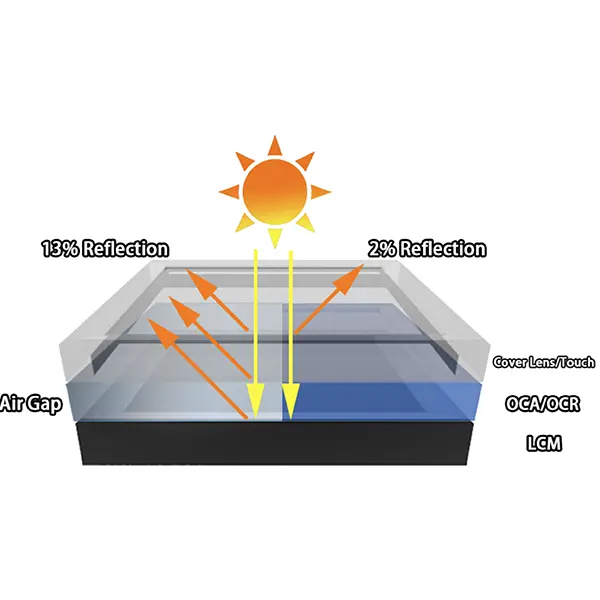

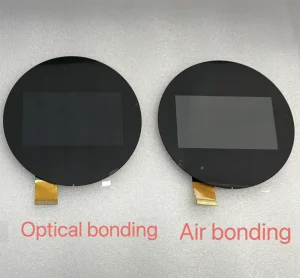

In many standard LCD displays, the cover glass and LCD panel are separated by a thin layer of air. This structure is known as *air bonding*, and while it’s cost-effective, it introduces a major optical flaw — internal reflection.

When light travels between materials with different refractive indices, such as glass and air, it bends and scatters. In an air-bonded display, ambient light passes through the cover glass, hits the air gap, and reflects multiple times before reaching the screen. This creates glare and reduces screen clarity under bright conditions. It also affects the light coming from the display’s backlight, making the screen appear dimmer in sunlight.

How Optical Bonding Solves the Glare Issue

Optical bonding removes the internal air gap by applying a layer of optically clear adhesive (OCA or OCR) between the cover glass and LCD panel. This adhesive closely matches the optical properties of the surrounding materials, creating a seamless path for light to travel.

As a result, light experiences far less refraction and reflection. More of the backlight reaches the user’s eyes, and less ambient light bounces around inside the screen. The outcome is significantly improved sunlight readability, better contrast, and more vibrant colors — even in outdoor environments.

For industrial, automotive, and smart home displays that must perform in direct sunlight, optical bonding isn’t just a benefit — it’s a necessity.