Introduction

Optical bonding technology has become a key focus in the development of modern LCD display modules, especially for industrial equipment, medical monitors, automotive dashboards, and embedded systems. As these devices are increasingly deployed in challenging environments, achieving clear and reliable screen visibility is more important than ever.

One of the most critical — yet often overlooked — elements in overall display performance is the bonding method used between the protective cover glass and the LCD panel. This technique directly affects sunlight readability, shock resistance, and long-term durability.

Optical bonding offers a practical solution by eliminating the air gap between display layers. This not only improves visual clarity but also enhances mechanical strength and environmental resistance. In this article, we’ll take a closer look at what optical bonding is, how it works, and why it’s becoming the standard in high-reliability display applications.

What Is Optical Bonding?

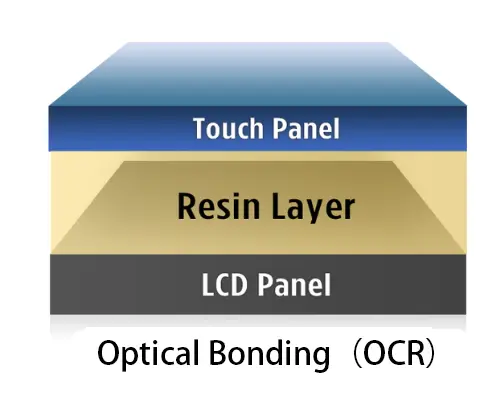

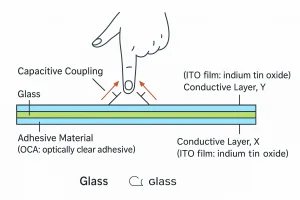

Optical bonding is a display lamination process where a layer of optically clear adhesive — typically OCA (Optically Clear Adhesive) or OCR (Optically Clear Resin) — is used to glue the LCD panel directly to the cover glass or touch screen. This eliminates the air gap that is typically present in conventional bonding methods.

The result is a single, unified optical layer that improves visibility and strengthens the overall structure. By removing internal reflections and minimizing light refraction, optical bonding allows more light to pass through the screen and increases contrast, especially in high-brightness or outdoor environments.

This process is also referred to as full lamination or gapless design, as it completely fills the space between layers with adhesive. The bonding is usually performed in a dust-free, controlled environment to ensure bubble-free, high-precision alignment.

How Optical Bonding Works

Optical bonding involves the precise lamination of three main components: the cover glass (or touch panel), the optically clear adhesive (OCA or OCR), and the underlying LCD panel. These layers are bonded together to form a seamless optical unit with no air gap in between.

In a typical air-bonded display, ambient light enters through the cover glass, partially reflects at the air-glass interface, and reflects again at the glass-LCD interface — creating internal reflections and reduced readability. Optical bonding eliminates these interfaces by filling the gap with a transparent adhesive, allowing light to pass directly through the stack with minimal reflection and scattering.

The result is a significant improvement in screen brightness, contrast, and sunlight readability. Since the adhesive matches the optical index of the surrounding materials, it reduces glare and enhances the effective transmission of light from the backlight to the user’s eyes.

In addition to better optics, optical bonding also enhances touch accuracy. Without an air gap, there is less parallax — meaning the visual and touch-sensitive layers are perfectly aligned. This creates a more natural and responsive user experience, especially important in capacitive touch applications.

Key Benefits of Optical Bonding

Display Performance Enhancements

- Excellent visibility even under strong sunlight, thanks to reduced internal reflections.

- Higher contrast and more vivid colors due to minimized glare and light scattering.

- Touch accuracy feels more responsive, as the screen registers input closer to where you touch.

Mechanical Strength & Environmental Protection

- The bonded layers offer better resistance to shock and vibration — useful for portable or industrial devices.

- No air gap means less chance for dust, moisture, or condensation to interfere with the display.

- Stronger construction contributes to fewer failures and longer operational lifespan in demanding conditions.

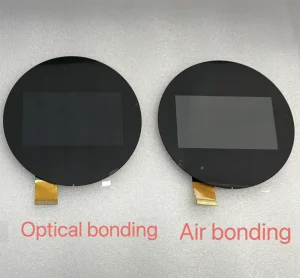

Optical Bonding vs. Air Bonding

When choosing between optical bonding and traditional air bonding, it’s important to evaluate the performance trade-offs in different use cases. The table below outlines key differences:

| Feature | Optical Bonding | Air Bonding |

|---|---|---|

| Reflection Rate | Low (better visibility) | High (causes glare) |

| Brightness Efficiency | Higher (better light transmission) | Lower (light lost in air gap) |

| Cost | Higher | Lower |

| Resistance to Moisture/Dust | Excellent | Poor (can trap particles) |

| Repair & Maintenance | Less convenient | Easy to separate and replace |

For instance, an outdoor kiosk or vehicle display will benefit greatly from optical bonding thanks to improved sunlight readability and environmental resistance. Meanwhile, an indoor tablet used in controlled conditions may function well with air bonding at a lower cost.

Common Applications of Optical Bonding

Many industrial HMI panels used in dusty factories or humid outdoor environments rely on optical bonding to maintain clarity over time — especially when touch accuracy is mission-critical. Optical bonding is widely adopted in industries where display performance, reliability, and environmental durability are essential. Below are some typical use cases:

- Industrial HMI Panels: Used in factory automation and process control environments that demand robust, sunlight-readable screens.

- Medical Devices: Surgical monitors and diagnostic equipment require high contrast and minimal reflection for clinical accuracy.

- Outdoor Terminals: Kiosks, POS systems, and ATMs benefit from improved durability and readability under sunlight and exposure to dust or moisture.

- Automotive Displays: Dashboard and HUD units must withstand vibration while maintaining clear readability in variable lighting.

- Smart Home Touch Panels: Optical bonding adds premium clarity and enhances touch accuracy for control interfaces in modern smart living systems.

These applications demand long-lasting, high-clarity displays — making optical bonding a critical part of next-generation display module design.

Conclusion and Future Outlook

Optical bonding has become a critical technology in modern display design, especially for embedded and industrial applications that demand high readability, durability, and environmental resistance.

While the initial cost is higher than traditional air bonding, the long-term advantages in terms of performance, longevity, and user experience are significant.

For project teams evaluating display modules, understanding the differences between bonding techniques is essential.

You can explore our in-depth comparison in the article

Air Bonding vs Optical Bonding: Which is Better for Your Display Project?

for a detailed side-by-side analysis.

Looking ahead, advancements in adhesive materials and lamination automation are making optical bonding more scalable and cost-effective.

With increasing demand for rugged, sunlight-readable, and ultra-clear displays in medical, automotive, and IoT sectors, the adoption of optical bonding is set to accelerate.

If you’re planning to use your display in a rugged, bright, or touch-intensive setting, optical bonding may be worth serious consideration. And if you’re looking for engineering support or a ready-to-go display platform, Rocktech can help — from concept to mass production.

Whether you’re building the next-gen HMI, outdoor kiosk, or smart home interface — choosing the right bonding method could define your product’s success.