1) Why Touchscreen Surface Treatments Matter for Industrial and Outdoor Displays

Touchscreen surface treatments such as AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), and HC (hard coating) go far beyond aesthetics. In outdoor sunlight, oily factory floors, high-touch retail, medical environments, and even gloved operation, a bare glass surface quickly becomes a bottleneck.

- Readability: control specular glare and ambient reflections to preserve contrast.

- Durability: resist scratches, abrasion, and chemicals used for cleaning.

- Cleanability: repel fingerprints and smudges; enable easy wipe-downs.

- Safety & hygiene: optional antimicrobial films, shatter resistance, and compliance with frequent disinfection.

A clear screen isn’t just nice to have—it’s the difference between a usable device and a frustrating one.

2) Common Touchscreen Surface Treatments: AG, AR, AF, HC and More

Anti-Glare (AG) in Touchscreen Surface Treatments

Principle: Micro-etching or coated micro-roughness scatters incident light to reduce mirror-like glare.

Typical metrics: Haze 5–25% (tunable), total transmittance (Tt), contrast retention.In our lab tests, low-haze AG at 10% improved kiosk readability by 25% in 500 lux environments.

Pros: Cuts glare from broad light sources; comfortable reading; hides minor fingerprints.

Trade-offs: Excessive haze lowers image sharpness and dark-on-light contrast.

Best for: Indoor bright areas, kiosks, HMIs with icon-driven UI, modest ambient reflection.

Anti-Reflection (AR) Treatment for IPS and Industrial Panels

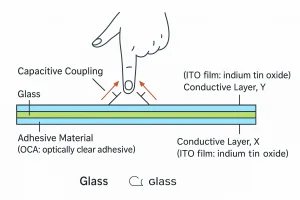

Principle: Multi-layer interference coatings reduce Fresnel reflection at the air–glass interface.

Typical metrics: Surface reflectance R% @ 550 nm < 1.0–1.5%, ΔE color shift, angle dependence.

Pros: High contrast, premium appearance, preserves detail and color fidelity.

Trade-offs: Higher cost; coating can scratch without HC; performance varies with viewing angle.

Best for: Outdoor signage, sunlit HMIs, retail displays where readability equals revenue.

Anti-Fingerprint (AF) / Easy-Clean (AS) Surface Finishes

Principle: Low-surface-energy topcoat (oleophobic/hydrophobic) reduces adhesion of oils/water and lowers friction.

Typical metrics: Water contact angle (WCA) > 105°, oil contact angle > 70°, slide/roll angle, coefficient of friction.

Pros: Smudges less visible; wipes clean quickly; smooth touch feel.

Trade-offs: Thin topcoats can wear; choose higher-end AF or combine with HC for longevity.

Best for: High-touch retail, public terminals, medical devices requiring frequent cleaning.

Hard Coating (HC) for Scratch Resistance in Touchscreens

Principle: UV-curable or sol-gel hardcoat increases surface hardness and abrasion resistance.

Typical metrics: Pencil hardness 3H/5H/7H/9H, Taber abrasion ΔHaze, scratch resistance.

Pros: Withstands wipes, dust, incidental contact; protects AR/AF layers beneath.

Trade-offs: Very high hardness can slightly alter tactile feel; formulation must preserve AF performance.

Best for: Industrial and medical deployments, public kiosks, logistics and warehousing.

Combining AG, AR, AF, and HC for Outdoor and High-Traffic Use

Principle: Stack coatings to balance reflection control, clarity, and cleanability.

Examples: AR + low-haze AG for sunlight; AR + AF for premium look with easy cleaning; HC beneath AF to extend life.

Best for: Outdoor, high-interaction devices that must look clear and stay clean.

Optional Antimicrobial and Anti-Mold Coatings for Medical and Public Devices

Principle: Embedded antimicrobial agents reduce microbial growth on surfaces.

Best for: Hospitals, food service, public terminals with cleaning SOPs.

At-a-Glance Comparison

| Treatment | Core Purpose | Typical Metric | Pros | Trade-offs | Best For |

|---|---|---|---|---|---|

| AG | Reduce specular glare | Haze 5–25% | Comfortable viewing; hides minor prints | Too much haze softens detail | Bright indoor HMIs, kiosks |

| AR | Lower surface reflectance | R% @ 550 nm < 1–1.5% | High contrast, vivid color | Cost↑; needs HC for scratch protection | Outdoor/readability-critical UIs |

| AF/AS | Resist fingerprints, easy clean | WCA > 105°, Oil CA > 70° | Smudge control; fast wipe-down | Topcoat wear; pair with HC | Retail, medical, public touch |

| HC | Scratch/abrasion resistance | 3H–9H, Taber ΔHaze | Longer life; protects AR/AF | May change tactile feel | Industrial/medical duty |

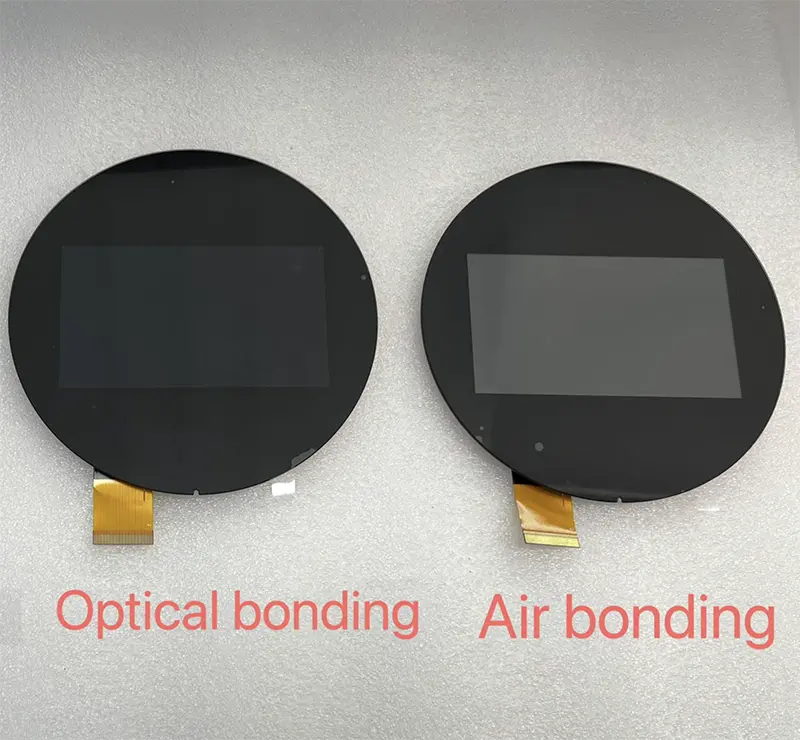

| OCA/LOCA* | Optical bonding (stack choice) | Air gap ≈ 0 | Big contrast gain in sun | Cost↑; rework harder | Outdoor HMIs, signage |

*This table highlights the trade-offs, but the right choice depends on your environment and how users interact with the screen.

3) Key Metrics & Test Methods

Optical metrics ensure the display remains legible under ambient light, while mechanical tests predict long-term durability.

- Optical: Haze (%), Total Transmittance (Tt), Surface Reflectance R% (550 nm), Contrast Ratio (CR) under ambient light.

- Surface energy / easy-clean: Water/oil contact angle, roll/slide angle, coefficient of friction.

- Mechanical: Pencil hardness (3H–9H), Taber abrasion ΔHaze, scratch resistance per ASTM standards.

- Chemical: Alcohols, IPA, detergents/disinfectants; salt-spray where relevant.

- Environmental: Thermal cycling, high-temp/low-temp soak, humidity, UV exposure (yellowing/adhesion).

- Touch performance: Finger/glove sensitivity, wet hand behavior, palm rejection, ghost touches after environmental stress.

4) Process & Stack Selection

Once the cover material is selected, the next step is to choose the right coating process.

Cover materials: Tempered or chemically strengthened glass for hardness and optical stability; PMMA/PC for light weight and impact resistance (accepting higher scratch risk).

Deposition/coating: Vacuum PVD/PECVD for AR; spin/spray-coat for AF/HC; chemical or mechanical etch for AG. Verify adhesion between layers and compatibility with downstream cleaning.

Bonding: Optical bonding (OCA/LOCA) removes the air gap, cutting internal reflections and dramatically improving sunlight contrast. Air-gap bonding is cheaper and more serviceable but adds reflective interfaces.

Display matching: With IPS panels, pair AR (low R%) and appropriate haze to protect contrast. Consider backlight brightness (nits), polarizer orientation, and any additional cover films to avoid color shift or Moiré with fine gratings.

5) Reference Recipes by Environment

- Outdoor / direct sun: High-brightness LCD (≥ 1000 nits) + AR (R% < 1–1.5%) + low-haze AG + optical bonding + AF topcoat.

- Industrial oil & gloves: Robust AF/AS (easy-clean) + high-hardness HC + glove touch tuning (controller thresholds, debounce, palm rejection).

- Medical / frequent disinfection: HC (7H–9H) + chemically resistant AF + optional antimicrobial; validate against approved cleaners and SOP cycles.

- Premium retail HMI: Low-R AR + high-clarity AF for optics + HC for longevity; prioritize color neutrality and low friction feel.

6) Selection Flow (From Requirements to Release)

- Environment definition: Indoors/outdoors, lux level, contamination, cleaning frequency, glove/wet-hand use.

- Touch specification: Finger vs glove, water tolerance, palm rejection, bezel vs edge-to-edge glass.

- Optical budget: Target surface reflectance and contrast in ambient; reconcile with available backlight nits.

- Stack proposal: Choose AG/AR/AF/HC combination and bonding type; build A/B samples.

- Pilot run: Run aging + cleaning + abrasion regressions; confirm touch stability after stress.

- Release: Freeze metrics and acceptance tests in the drawing/quality docs; specify maintenance and cleaning SOP.

7) Acceptance & Mass-Production Control

- Incoming: Visual defects, coating uniformity, haze/reflectance spot-checks, adhesion (tape test).

- In-process: Bonding cleanliness (no bubbles/particulates), alignment, film thickness control, curing parameters.

- Final: Optical, mechanical, chemical wipes, and touch stability; retain “golden sample”.

- Reliability sampling: Periodic temp/humidity/UV/chemical re-validation to catch drift in upstream materials.

- Care guide: Approved cleaners, cloth types, and intervals to preserve AF performance and avoid AR damage.