Introduction to PCAP Technology and Touch Display Structures

Touchscreen technology is now essential in both industrial and consumer electronics. PCAP (Projected Capacitive) touch panels are widely used for their durability, sensitivity, and clear visual performance.

What Is PCAP and How It Works

PCAP technology detects touch through changes in capacitance when a finger approaches the screen surface. A transparent grid of conductive electrodes forms an electric field, and the system senses the location of the touch by measuring the disturbance. This structure enables multi-touch control, high transparency, and fast response, making PCAP the foundation for modern touch solutions such as GG display, GFF display, OGS display, in cell display, and on cell touch display.

Why Different Touch Structures Exist

Although all are based on capacitive sensing, their layer designs and integration methods differ. Each type—GG, GFF, OGS, in-cell, and on-cell—was developed to meet specific needs for cost, thickness, optical clarity, and durability.

Traditional structures like the GG display offer excellent strength for industrial use, while in-cell and on-cell technologies focus on thinner, more integrated solutions for smart devices. The evolution of these structures shows how touchscreen design continues to balance performance, appearance, and manufacturing efficiency.

Traditional Touch Panel Structures – GG Display, GF Display, and GFF Display

Before advanced integrated technologies like in-cell and on-cell appeared, traditional PCAP touch structures such as GG, GF, and GFF were the most common in the market. Each structure offers a different balance of cost, thickness, and durability.

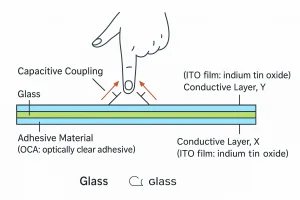

GG Display (Glass+Glass)

The GG display uses two layers of glass—one as the cover lens and one as the sensor substrate. This structure provides excellent strength, optical clarity, and long lifespan, making it ideal for industrial, automotive, and outdoor applications. However, it is relatively heavier and more expensive compared with other types.

GF Display (Glass+Film)

The GF structure combines a glass cover with a film sensor. It is thinner and lighter than a GG display, while still offering good durability. GF is often chosen for home appliances and portable devices, where weight and cost are important considerations.

GFF Display (Glass+Film+Film)

The GFF display replaces the glass sensor with two layers of conductive film. This design offers better flexibility, lower cost, and easier customization for curved or compact devices. However, the optical clarity and surface hardness are slightly lower than GG.

Comparison of GG, GF, and GFF Displays

| Structure | Layer Composition | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|

| GG Display | Glass + Glass | Excellent durability, high clarity | Heavy, higher cost | Industrial, Automotive |

| GF Display | Glass + Film | Thin, lightweight, moderate cost | Less durable | Consumer electronics |

| GFF Display | Glass + 2 Films | Flexible, cost-effective | Lower transparency, softer surface | Wearables, small devices |

Next-Generation Structures: OGS, On-Cell, and In-Cell Displays

As the demand for thinner, lighter, and more integrated devices grows, new touch display structures have emerged — OGS (One Glass Solution), On-Cell, and In-Cell. These designs aim to simplify construction, reduce thickness, and enhance optical clarity while maintaining excellent touch performance.

OGS (One Glass Solution)

OGS replaces one layer of glass from the traditional GG structure. The touch sensor is directly patterned onto the cover glass instead of using two separate glass substrates.

This structure eliminates one layer of adhesive and glass, making the module thinner, lighter, and more transparent. OGS is commonly used in smartphones, tablets, and high-end portable devices where compact design and display clarity are critical.

However, because the touch sensor is integrated into the cover glass, once it is damaged, both the touch and display often need to be replaced together, which may increase repair costs.

On-Cell

In an On-Cell display, the touch sensor is integrated directly onto the top of the display’s glass (TFT glass) before the polarizer layer. This structure allows manufacturers to maintain separate production of the touch and display while still achieving a thinner design than GG or GFF.

On-Cell offers a good balance between cost, thickness, and performance. It provides faster touch response, better optical performance, and durability for consumer and industrial applications.

In-Cell

In-Cell technology goes one step further by embedding the touch sensor directly inside the display cell — within the LCD or OLED structure itself. This high level of integration enables the thinnest and lightest designs with superior optical clarity and touch accuracy.

In-Cell displays are widely used in premium smartphones, tablets, and laptops. However, their production process is more complex, and customization flexibility is lower compared to modular GG or GFF solutions, which makes them less common in industrial or custom-size applications.

Comparison Summary – Which Structure Fits Your Application?

Choosing the right touch display depends on durability, optical clarity, thickness, cost, and the intended use. Here’s a concise comparison:

Optical Clarity and Thickness

-

GG display: excellent clarity, thicker and heavier.

-

GFF display: thinner and flexible, slightly lower transparency.

-

OGS display: thinner than traditional designs, high transparency.

-

On-Cell and In-Cell displays: thinnest, best optical performance, ideal for premium devices.

Durability and Cost

-

GG display: most durable, higher cost.

-

GFF display: balanced cost and durability for consumer devices.

-

OGS, On-Cell, In-Cell: highly integrated and thin, but repair and production can be more complex.

Application Recommendations

| Application | Recommended Display | Reason |

|---|---|---|

| Industrial | GG Display | Durable and reliable |

| Consumer | GFF Display | Flexible, cost-effective |

| Smartphone | In-Cell Display | Ultra-thin, high clarity |

| Tablet | OGS Display | Thin and lightweight |

| Laptop | On-Cell Touch Display | Balanced thickness and performance |

In short, GG and GFF display suits industrial or custom applications, while OGS, In-Cell, and On-Cell are preferred for thin, high-performance consumer devices.

Market Trends & Conclusion

The touchscreen industry continues to evolve toward thinner, lighter, and more integrated designs. Technologies like in cell display and on cell touch display are becoming standard in smartphones, tablets, and premium laptops, while OGS displays offer a simpler, cost-effective approach for compact devices.

Despite this trend, traditional structures such as GG display and GFF display remain important in industrial, automotive, and rugged applications due to their durability and reliability.

Choosing the right touch panel requires balancing performance, cost, and application needs. Whether it’s a robust GG display for industrial control or a sleek in-cell display for a high-end device, selecting the appropriate technology ensures the best user experience and long-term product success.