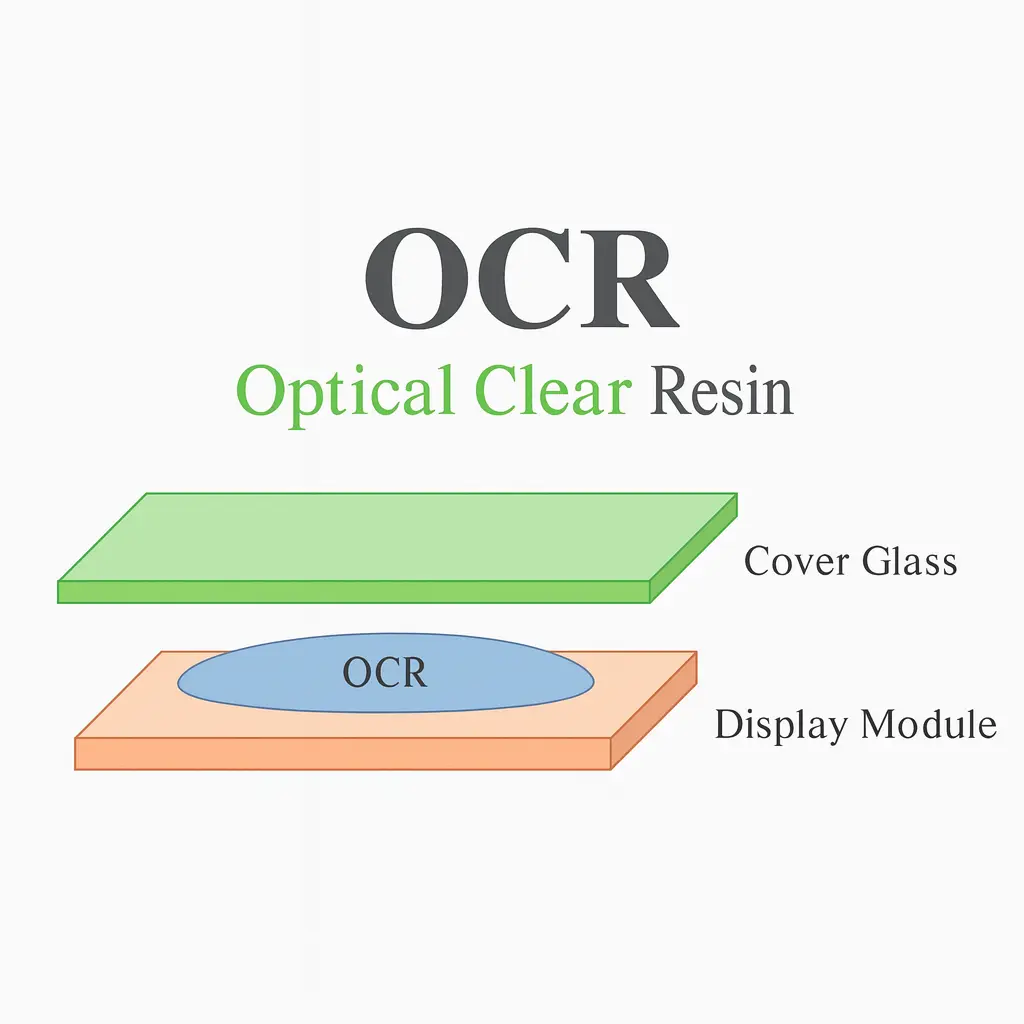

OCR (Optically Clear Resin) is a liquid adhesive designed for optical bonding between cover glass, touch sensors, and display modules. Unlike OCA (film-based bonding), OCR fills uneven gaps and complex geometries, making it the preferred choice for curved or stepped display designs. This article explains OCR’s properties, process, advantages, limitations, and applications in industrial and consumer products.

What Is OCR?

OCR is a UV- or thermal-curable liquid adhesive with high optical transparency (>98% transmittance) and low haze (<1%). It is formulated to match the refractive index of glass or plastic to minimize internal reflections. Because it is dispensed as a liquid, OCR can flow into non-uniform gaps, filling every micro-void between layers for superior optical and mechanical bonding.

How OCR Bonding Works

- Surface preparation: Clean and treat bonding surfaces to remove dust, oil, and moisture.

- Dispensing: Apply a precise volume of OCR to the display or cover surface, often in a spiral or grid pattern.

- Stacking: Carefully align and place the second component, allowing the resin to spread and fill all gaps.

- Curing: Use UV light, heat, or a combination to cure the resin into a solid, optically clear layer.

- Finishing: Trim excess resin and clean edges for a dust-free, smooth finish.

Advantages of OCR

- Fills complex geometries: Ideal for curved cover glass, deep steps, or uneven gaps that films cannot handle.

- Superior adhesion: Forms a strong, permanent bond for vibration and impact resistance.

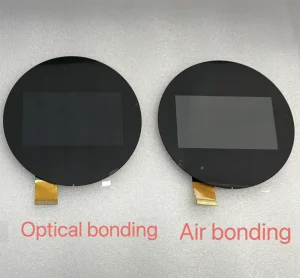

- Enhanced optical performance: Eliminates air gaps for higher contrast, better sunlight readability, and reduced reflection.

- Improved durability: Resistant to moisture ingress and temperature fluctuations when properly sealed.

Limitations of OCR

- Longer process time due to resin curing.

- Requires precise dispensing to avoid bubbles or overflow.

- Harder to rework after curing compared to OCA film.

- May need special fixturing and curing equipment for large-scale production.

Typical OCR Applications

- Automotive dashboards with curved cover glass.

- High-end industrial HMIs with uneven sensor integration.

- Wearable devices with small-radius curves.

- Specialized optical instruments requiring precise gap filling.

OCR vs. OCA (Quick Comparison)

| Criteria | OCR (liquid resin) | OCA (film) |

|---|---|---|

| Gap filling | Excellent, fills any shape | Limited to flat gaps |

| Process speed | Slower (due to curing) | Faster (no cure) |

| Reworkability | Very difficult after cure | Possible in early stage |

| Equipment cost | Higher (dispensing + curing) | Lower (lamination press) |

For flat-panel, high-speed production lines, OCA is often more efficient. For complex geometries or premium designs, OCR delivers better fit and performance.

Design & Manufacturing Tips

- Control dispensing: Use automated dispensers to ensure even coverage and minimize trapped air.

- Optimize curing: Match UV wavelength or thermal profile to the resin type for full cure without yellowing.

- Environmental testing: Validate with damp heat, thermal cycling, and vibration tests to ensure long-term reliability.

- Cleanroom environment: Prevent dust contamination, which can cause visible defects in cured resin.

Partner With an Experienced Optical Bonding Provider

OCR bonding requires precision and cleanroom expertise. Partnering with a manufacturer experienced in both OCR and OCA processes ensures you select the right bonding method for your design.