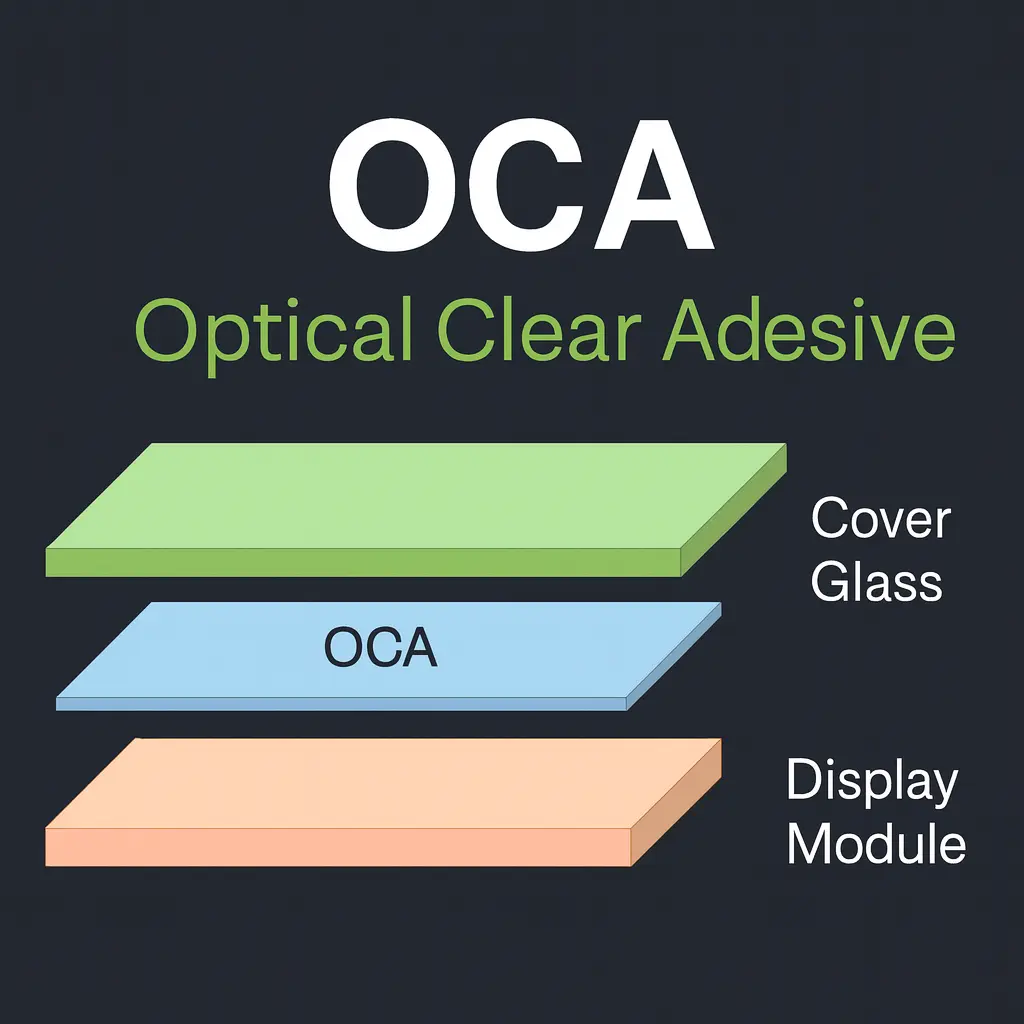

OCA (Optically Clear Adhesive) film is the industry-standard dry bonding material for laminating cover lenses, touch sensors, and TFT LCD/AMOLED modules. It improves optical performance, durability, and user experience without the mess of liquid curing. This guide explains what OCA is, how it works, where it fits best, and the key design choices to get right in production.

What Is OCA?

OCA is a highly transparent, double-sided pressure-sensitive adhesive (PSA) supplied as a film on release liners. It is engineered for very low haze (<1%), high transmittance (typically > 98%), and excellent refractive index matching to glass and plastic. Because it is a dry film, OCA avoids liquid flow, mixing, and curing—making it ideal for clean, predictable, and scalable optical bonding.

How OCA Bonding Works

- Surface prep: Clean and plasma/UV treat glass or plastic surfaces to improve adhesion and reduce particles.

- Lamination: Laminate OCA to the cover lens or touch sensor using a roller or lamination press in a cleanroom.

- De-bubble: Vacuum de-air to remove microbubbles at the edges or within texture features.

- Stacking: Align and laminate the second interface (e.g., touch to display) and perform a final de-bubble cycle.

Because OCA is pressure-activated, there is no liquid flow, edge dam, or long thermal cure—greatly simplifying fixtures and takt time.

Why Engineers Choose OCA

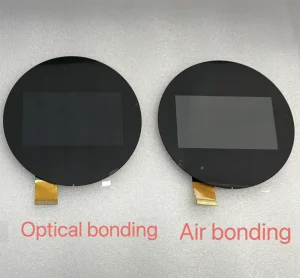

- Superior readability: Eliminates the air gap, reducing internal reflections and boosting contrast for outdoor use.

- Clean, repeatable process: No liquid handling or cure variability; excellent for mass production.

- Thin, light, and clear: Multiple thicknesses (e.g., 50–250 μm) to tune stack height while maintaining high transmittance.

- Reliability: Proven resistance to yellowing, humidity, and thermal cycling with the right material grade and stack-up.

- Reworkable (early stage): Short-window rework is possible before full set, reducing scrap during NPI.

Typical Use Cases

- Industrial HMIs, smart thermostats, handheld instruments, and vehicle displays that need vibration resistance and sunlight readability.

- Medical devices where optical clarity and low particulates are critical.

- Consumer electronics (phones, tablets, wearables) where thin, high-quality touch/display stacks are required.

OCA vs. OCR (Quick View)

| Criteria | OCA (film) | OCR (liquid resin) |

|---|---|---|

| Process | Dry lamination; no cure | Dispense + cure (UV/thermal) |

| Complex shapes/gaps | Best for flat & uniform gaps | Fills uneven gaps and steps |

| Takt time | Short, highly repeatable | Longer (curing + fixturing) |

| Rework | Limited early rework | Difficult after cure |

Rule of thumb: choose OCA for flat stacks and high-volume production; choose OCR when you must fill non-uniform gaps, curved covers, or deep steps. (A dedicated “OCA vs OCR” deep-dive will follow.)

Design & Material Tips

- Pick the right thickness: Match OCA thickness to the mechanical gap and target stiffness; thin film for rigid stacks, thicker film to absorb tolerances.

- Match CTE & modulus: Consider glass vs. plastic CTE and select OCA grades that minimize stress over temperature.

- AR/AF/AG treatments: Combine OCA with anti-reflective, anti-fingerprint, or anti-glare coatings to optimize sunlight performance.

- Reliability tests: Validate with damp heat (85/85), thermal shock, UV exposure, and vibration according to your industry standard.

Work With a Manufacturing Partner

If you need an end-to-end optical bonding stack (cover glass, touch sensor, display, and OCA) with cleanroom lamination and reliability validation, we can help. Explore: