Industrial control environments are tough—dust, water splashes, and corrosive debris are daily challenges. IP65-rated industrial touchscreens are built to survive these conditions, making them a cornerstone of reliable production line monitoring.

-

What IP65 Means: The certification combines two key protections: 100% dustproof (no particles penetrate, even in heavy industrial dust) and resistance to low-pressure water jets (withstands 12.5 liters/min for 3 minutes). This makes them ideal for food processing plants (where washdowns are frequent) or metal workshops (dusty with oil splatters).

-

Pain Point: High-pressure washdowns (used to sanitize equipment) and occasional spills expose screens to moisture. Non-IP65 screens often short-circuit, requiring monthly replacements and 4+ hours of unplanned downtime per failure.

-

Choosing the Right Protection: IP65 works for 80% of industrial settings. Higher ratings like IP69K (for high-pressure steam cleaning) cost 40% more and are only necessary for specialized environments (e.g., dairy processing). For most production lines, IP65 balances durability and cost.

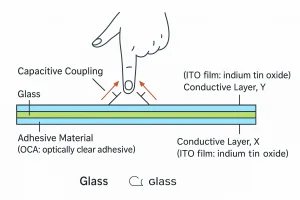

Operators in factories, cold storage, or labs rely on gloves for safety—but traditional touchscreens often fail to respond through them, slowing work an

d raising risks.

- Metal processing and heavy machinery: Operators handling sharp components or heavy equipment need to use cut-resistant gloves (Kevlar or wire mesh lined gloves). These gloves are thick enough to prevent blade cuts but have almost zero conductivity, which causes the setting time of the press machine to be much slower because workers wearing gloves have difficulty inputting parameters.

- Pharmaceuticals and laboratory environments: To prevent contamination, sterile gloves must be used, but removing gloves to use the touchscreen exposes samples to pathogens, which could lead to costly batch recalls because operators may accidentally touch reagent bottles while adjusting screen settings. These data clearly reveal a problem with screen issues related to gloves, causing time waste and loss of productivity.

- Designed for industrial environments: Different from consumer-grade touch screens, Rocktech’s solution is strengthened and suitable for the harshest conditions. Its standard industrial CTP solution can precisely address the aforementioned issues. It is assorted and supports waterproofing, industrial glove operation, anti-fingerprint and thicker lenses, irregular shapes, and various surface treatments

Industrial touchscreens serve as the central nervous system of modern production lines, bridging data silos and turning fragmented information into actionable insights—critical for reducing waste and maximizing uptime.

-

Disconnected Systems and Delayed Alerts: Traditional manufacturing environments often operate with a patchwork of tools: PLCs buried in control cabinets, sensor data logged in spreadsheets, and critical alerts buried in email chains. This fragmentation creates dangerous delays. For example, an overheating motor in a stamping line might trigger a sensor warning, but if that data isn’t visible to operators until their hourly log check, the motor could seize—may costing 8+ hours of downtime and $50,000 in repairs. Similarly, low material levels in a packaging line might go unnoticed until the conveyor jams, leaving 200+ unfinished units and missed shipping deadlines.

-

Solution: Imagine a production floor where data doesn’t just flow—it collaborates. Where the barriers between machines, sensors, and decision-makers dissolve into a single, intuitive pulse that keeps pace with the speed of your operation. This isn’t just about connecting tools; it’s about weaving a fabric of intelligence that turns chaos into harmony. Modern industrial touchscreens integrate with PLCs via Modbus/Profinet, displaying live data (temperatures, pressure, counts) on a single dashboard.

Not all screens fit every environment—here’s what to prioritize:

-

Environmental Toughness: Industrial environments vary drastically, and screens must stand up to your specific conditions. Foundries and metalworking shops, where heat and vibration are constant, need screens tested to withstand 20g acceleration to resist shaking from nearby machinery. Outdoor or dusty settings benefit from IP65 or higher ingress protection to block particles and moisture. A screen that thrives in a food processing plant might fail in a desert facility without proper thermal management—matching the screen to your environment directly impacts its 3–5 year lifespan.

-

Compatibility: The best touchscreen is useless if it can’t “talk” to your existing equipment. Look for models preloaded with drivers for your PLCsand HMI software. This eliminates the need for custom coding, which can add 20–40 hours of IT work and risk compatibility bugs.Always check the manufacturer’s compatibility matrix—most reputable brands list supported systems upfront to prevent costly mismatches.

-

Cost vs. Needs: Industrial touchscreens range from basic to feature-rich, but more expensive doesn’t always mean better for your use case. Focus on non-negotiables (e.g., IP65 protection for wet areas, glove compatibility for cold storage) and trim frills that don’t impact your daily operations. This approach can reduce upfront costs by 20–30% without sacrificing reliability.

-

Anti-Glare & Anti-Fingerprint: Coatings that reduce reflections (under 5%) and repel smudges will make screens easier to read in bright factories.

-

Edge AI: Screens will analyze camera feeds to spot defects (e.g., cracked bottles) in real time, cutting waste.

-

Sustainability: Models with 60% recycled materials (aluminum frames, recycled glass) align with eco-friendly factory goals, reducing e-waste.

These industrial touchscreens—with IP65 protection, glove-friendly design, and smart monitoring—are more than tools: they’re the backbone of efficient, safe production lines. For businesses aiming to boost output and cut downtime, the right screen isn’t an expense—it’s an investment.