Introduction to Capacitive Touchscreens

What Is a Capacitive Touchscreen?

A capacitive touchscreen is a type of touch-sensitive interface that uses the electrical properties of the human body to detect input.

Unlike resistive touchscreens, which rely on physical pressure to register touch, capacitive panels sense changes in electrostatic fields caused by the presence of a conductive object—typically a finger.

This enables faster response times, multi-touch capability, and a more intuitive user experience.

Why Are Capacitive Touchscreens So Common Today?

While capacitive touchscreens dominate today’s consumer and industrial markets, that wasn’t always the case.

In the early days of touchscreen development, resistive touch panels were more common due to their low cost and ability to work with any input tool—including gloved hands or styluses.

However, this technology suffered from limited clarity, poor durability, and lack of multi-touch functionality.

The real turning point came with Apple’s first iPhone, introduced by Steve Jobs in 2007.

The iPhone popularized capacitive touchscreens by overcoming key limitations such as sensitivity, gesture recognition, and smooth glass interfaces.

Since then, rapid advancements in material science, sensor integration, and driver software have made capacitive touchscreens not only viable but superior in most applications.

Capacitive vs. Resistive: A Quick Comparison

| Feature | Capacitive Touchscreen | Resistive Touchscreen |

|---|---|---|

| Input Type | Conductive (finger, stylus) | Any object (finger, stylus) |

| Multi-Touch Support | Yes | Limited |

| Durability | High (no pressure needed) | Medium (pressure wears layers) |

| Optical Clarity | Excellent (fewer layers) | Lower (multiple film layers) |

| Cost | Moderate to High | Low |

| Usage Environments | Consumer, industrial, medical | Rugged, outdoor, gloves needed |

Today, resistive panels are mostly reserved for niche applications—such as in harsh environments or when users must wear thick gloves.

In nearly all other cases, capacitive touchscreens have become the standard due to their performance, aesthetics, and ease of use.

Basic Working Principle

The Role of the Human Finger and Electric Fields

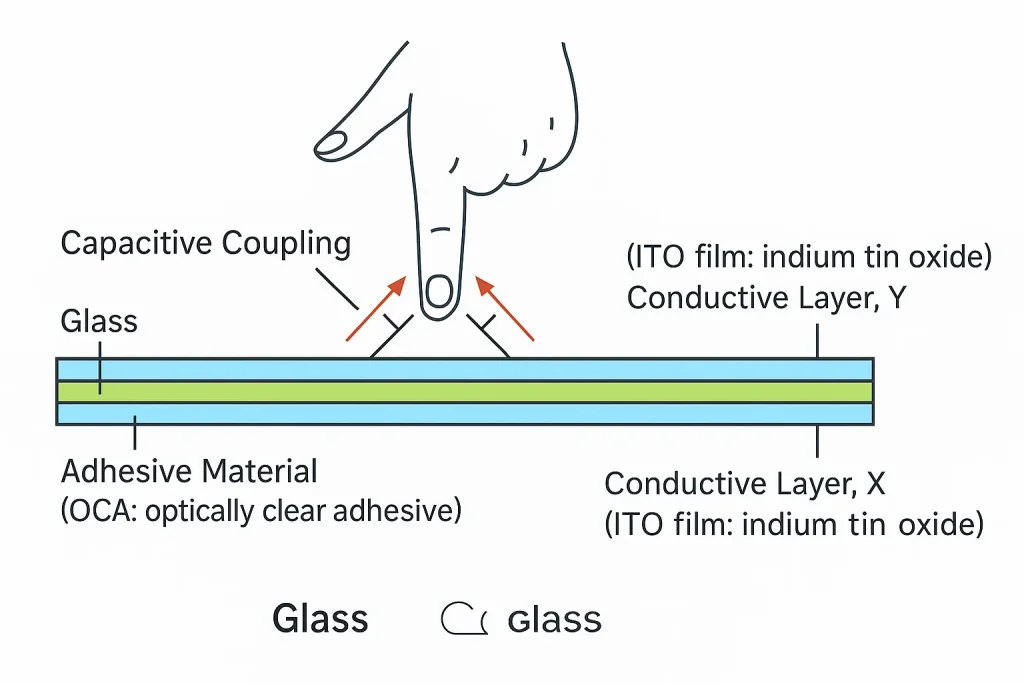

Capacitive touchscreens operate based on the principle of electrostatic fields.

When a human finger, which conducts electricity, comes close to or touches the surface of the screen, it alters the local electrostatic field.

This change is detected by the touchscreen controller and interpreted as a touch input.

Because it relies on the conductivity of the human body, capacitive screens respond without requiring pressure—resulting in smoother, more sensitive operation.

Self-Capacitance vs. Mutual Capacitance

There are two primary methods for detecting touch in capacitive systems:

self-capacitance and mutual capacitance.

Self-capacitance measures the change in capacitance of individual electrodes when touched, offering high sensitivity but limited multi-touch accuracy.

Mutual capacitance, on the other hand, detects changes between crossing rows and columns of conductive lines, allowing true multi-touch detection and more complex gesture recognition.

Modern smartphones and tablets typically use mutual capacitance for its enhanced performance.

Charge Transfer and Signal Processing

Once a touch is detected through capacitive changes, the raw signals are processed by the touch controller IC.

This IC interprets the input location and timing, filters noise, and sends coordinate data to the operating system.

Advanced touch ICs support features such as water resistance, glove touch, and thick cover glass detection through sophisticated signal processing and higher drive voltages.

Structure and Materials

ITO Layers and Transparent Electrodes

Capacitive touchscreens are built using ITO (Indium Tin Oxide) layers that serve as transparent conductive electrodes.

These are patterned into rows and columns—forming a grid that detects touch events at their intersections.

The more lines per inch (LPI) and the finer the pattern, the higher the touch resolution.

However, increasing electrode density also raises production costs and requires more powerful touch ICs to maintain performance.

In high-end industrial or medical applications where touch precision and responsiveness are critical, denser ITO patterns are preferred despite the higher cost.

Cover Glass and Protective Layers

Above the ITO layers sits the cover glass, which protects the sensor and enhances user interaction.

Standard consumer devices typically use 0.7–1.1 mm thick glass.

However, in industrial, public, or vandal-resistant environments, much thicker cover glass—ranging from 4 mm to 8 mm—is required.

To drive signals through such thick glass, the touch controller must offer stronger signal-driving capabilities.

Only high-performance ICs with enhanced sensitivity and noise immunity can support such use cases effectively.

Flexible vs. Rigid Touch Panels

Capacitive touchscreens can be manufactured in both rigid and flexible forms.

Rigid panels are built on glass or hard substrates and are commonly used in phones, kiosks, and control panels.

Flexible panels use PET or film substrates and are suited for applications where curved surfaces or lightweight designs are needed.

Each type offers trade-offs in durability, cost, and design flexibility.

Typical Applications in Industry and Consumer Electronics

Smartphones and Tablets

Capacitive touchscreens are the standard in modern smartphones and tablets due to their high sensitivity, multi-touch support, and excellent visual clarity.

They allow for gestures like swiping, pinching, and zooming—creating an intuitive user experience that revolutionized personal electronics starting with the original iPhone.

Industrial Control Panels

In industrial environments, capacitive touch panels are used in HMIs (Human-Machine Interfaces) for process monitoring and equipment control.

With enhanced durability, glove support, and the ability to withstand moisture and contaminants, they outperform traditional resistive touchscreens in demanding use cases.

Learn more about our custom TFT display solutions tailored for industrial panels.

Medical Devices

Medical-grade capacitive touchscreens are designed for diagnostic devices, monitors, and portable equipment.

These screens must be easy to clean, responsive even through gloves, and compliant with strict hygienic and regulatory standards.

Thanks to their sealed surface and high optical quality, capacitive panels are ideal for modern medical applications.

Smart Home Interfaces

Touch-enabled interfaces in smart home devices—such as thermostats, light switches, intercoms, and control panels—commonly use capacitive technology.

They provide a sleek, modern look and a responsive experience that fits the design expectations of today’s smart environments.

Advantages of Capacitive Touchscreens

Multi-Touch Capability

Capacitive touchscreens support true multi-touch functionality, allowing multiple fingers to interact with the screen simultaneously.

This is essential for complex gestures and intuitive UI interactions, which are standard in consumer electronics and increasingly in industrial systems.

High Clarity and Responsiveness

With no need for a flexible top layer (as in resistive screens), capacitive displays maintain excellent optical clarity.

Their glass surface ensures smooth touch response and better durability, while offering precise control without the need for pressure.

Durability and Low Maintenance

The use of toughened glass and sealed surfaces makes capacitive touchscreens highly durable and resistant to scratches, dust, and liquid ingress.

They require little maintenance and are suitable for environments where cleanliness and reliability are critical.

Water Interference and Gloves

While early capacitive screens struggled with water and glove input, modern touch ICs have largely overcome these challenges.

Today’s high-end panels offer water-rejection algorithms and glove detection—making them practical for outdoor, medical, and industrial applications.

Conclusion

Future Trends in Touchscreen Technology

The future of capacitive touchscreens includes further improvements in gesture recognition, 3D touch, force sensing, and integration with flexible and foldable displays.

With increasing adoption in automotive, healthcare, and wearable tech, capacitive technology continues to evolve rapidly.

Why Capacitive Touchscreens Continue to Dominate

Thanks to their superior user experience, aesthetics, and durability, capacitive touchscreens remain the dominant choice in both consumer and industrial markets.

Whether you’re developing a mobile device or designing a custom embedded display interface, capacitive panels offer unmatched performance and flexibility for a wide range of applications.