As industries demand more intelligent, interactive, and durable human-machine interfaces (HMI), the need for a custom touch screen display has grown dramatically. Whether for medical diagnostics, factory automation, outdoor kiosks, or smart appliances, Custom Displays tailored to specific application environments are key to product performance and user satisfaction.

This article explores how Capacitive Touch Screen customization, including FPC design, cover lens, bonding methods, surface treatment, and IC integration, helps customers achieve more competitive and reliable industrial display solutions.

Why Custom Touch Screen Displays Are Essential for Modern Industrial Displays

Growing Demand for Custom Displays Across Industries

From rugged tablets in oil fields to intuitive UIs on medical instruments, custom touchscreen displays are used across a variety of sectors. Standard modules often fail to meet the specialized needs of high-reliability environments, which drives OEMs to seek Custom Displays with tailored features, form factors, and functionality.

Benefits of Tailored Capacitive Touch Screen Solutions

With a custom capacitive touch screen, businesses gain:

-

Design freedom for housing integration

-

Enhanced environmental resistance

-

Better optical performance

-

Branding opportunities via silkscreen/logo printing

These advantages are essential in harsh or highly aesthetic applications like industrial displays, consumer devices, and smart retail systems.

Flexible CTP FPC Design for Custom Touch Screen Integration

Custom FPC Shape, Pin Definitions, and Connectors

The FPC (Flexible Printed Circuit) is the bridge between the touch panel and the system board. In custom projects, the FPC can be redesigned for:

-

Unique shapes to fit compact housings

-

Custom pin definitions

-

Connector location adjustments

-

Various interface types like I²C, USB, or SPI

This flexibility allows custom touch screen displays to be seamlessly integrated into existing product enclosures.

Compatibility with Multiple Touch ICs and Interfaces

Different Capacitive Touch Screen applications may require different ICs. We support integration with popular controllers like Goodix, ILITEK, Sitronix, or FocalTech, ensuring compatibility with Android, Linux, or Windows-based systems. Features like waterproof touch, glove mode, or stylus input are also customizable depending on the IC.

Cover Lens Customization in Capacitive Touch Screen Development

Custom Sizes and Glass Thickness Options

We offer Custom Displays ranging from 1.3” to 15.6” or beyond, with tailored glass thicknesses (0.7mm–6mm). Thicker glass improves durability in industrial displays, while thinner glass is preferred for compact devices.

Irregular-Shaped Cutting for Unique Touch Displays Designs

To support unique product designs, we provide non-standard shapes such as round, oval displays, along with cutouts, notches, and through-holes for components like cameras, LEDs, or mechanical buttons. These features are widely used in medical, automotive, and specialized industrial applications.

Logo and UI Printing

We support silkscreen printing of logos, borders, and functional icons directly on the cover lens, enhancing both product branding and user interface clarity.

High-Strength Glass Options

For demanding environments, we offer Gorilla Glass, Dragontrail, and other strengthened glass options, providing superior impact resistance, scratch protection, and optical clarity.

Surface Treatments That Enhance the Durability of Industrial Displays

Optical Coatings for Better Visibility

To improve the user experience in harsh lighting environments, we offer several surface treatments commonly used in industrial and outdoor displays:

-

Anti-Glare (AG): Diffuses ambient light to reduce harsh reflections, improving readability in bright settings.

-

Anti-Reflective (AR): Increases light transmission and reduces mirror-like glare for clearer viewing.

-

Anti-Fingerprint (AF): Minimizes smudges from skin contact and supports easy cleaning — especially valuable for medical, public-access, or frequently used touchscreens.

Environmental Protection Coatings for Industrial Touchscreens

Industrial, medical, and outdoor devices often require added durability and resistance to environmental hazards:

-

Anti-UV Coating: Shields the display from ultraviolet radiation, preventing yellowing and extending product lifespan.

-

Anti-Static Coating: Reduces the risk of electrostatic discharge (ESD), protecting internal circuits.

-

Anti-Shelter Treatment: Maintains screen clarity and touch responsiveness in rain, humidity, or dusty conditions.

| Treatment | Abbreviation | Function / Benefit |

|---|---|---|

| Anti-Glare | AG | Diffuses light, reduces reflection, improves outdoor readability |

| Anti-Reflective | AR | Increases light transmission, minimizes mirror-like glare |

| Anti-Fingerprint | AF | Resists smudges, supports easy cleaning, ideal for public use |

| Anti-UV | – | Prevents yellowing, extends product lifespan |

| Anti-Static | – | Protects against electrostatic discharge (ESD) |

| Anti-Shelter | – | Ensures clarity and responsiveness under rain, dust, or humidity |

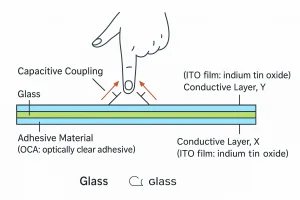

Bonding Technologies for High-Performance Custom Touch Screen Displays

The bonding method between the touch panel and display plays a critical role in determining the visual quality, durability, and overall performance of custom touchscreen displays. The three most common bonding techniques are Air Bonding, OCA Bonding, and LOCA Bonding.

-

Air Bonding

Air bonding leaves a small air gap between the touch panel and the display. While it is cost-effective and widely used in applications where performance demands are lower, it tends to reduce sunlight readability and optical clarity, and provides limited resistance to impact or moisture. -

OCA Bonding (Optically Clear Adhesive Film)

This method uses a transparent adhesive film to fully bond the touch panel to the display. It eliminates internal reflections, enhances contrast and clarity, and offers improved dust and moisture resistance, making it suitable for mainstream industrial and commercial displays. -

LOCA Bonding (Liquid Optically Clear Adhesive)

LOCA uses a UV-curable liquid adhesive that fills all gaps between the display layers. It delivers the highest optical performance, superior impact resistance, and is ideal for curved or irregular surfaces and high-end applications where display quality is critical.

Comparison Table: Air Bonding vs Optical Bonding

| Feature | Air Bonding | Optical Bonding (OCA/LOCA) |

|---|---|---|

| Definition | Air gap between display and touch panel | Optical adhesive fills gap, no air |

| Visual Quality | Lower contrast, reflections due to air gap | Higher contrast, reduced reflections |

| Brightness | Light loss from air gap | Better brightness and color accuracy |

| Dust & Moisture | Air gap can trap dust/moisture | Sealed, better dust/moisture protection |

| Durability | Less impact resistance | Improved strength and durability |

| Repairability | Easier to replace components | More difficult and costly to repair |

| Cost | Lower cost | Higher cost |

| Typical Use | Budget or less demanding applications | High-end, outdoor, industrial uses |

Application-Oriented Custom Touch Screen Requirements

Medical Equipment: High Clarity, Anti-Bacterial Surface, and High Sensitivity

Medical devices such as diagnostic scanners, patient monitors, and infusion pumps typically require:

-

Optical bonding (OCA) for better clarity and hygiene

-

Anti-reflective and anti-fingerprint coatings for clean usability

-

Glove-friendly capacitive touch screen for operation in sterile environments

-

Custom cover glass with printed UI icons and logo branding

Industrial HMIs: Rugged Design, Glove Touch, and ESD Protection

Industrial displays used in factory automation or control panels often need:

-

Thick cover glass (up to 6mm) with Gorilla Glass for impact resistance

-

Anti-glare or anti-static surface treatment

-

Custom FPC design for flexible system integration

Smart Home Devices: Aesthetic Design, Compact Size, and Brand Identity

Smart thermostats, kitchen displays, or home control panels require:

-

Irregular shape cuttings (round, oval) for modern aesthetics

-

Slim glass with logo/silkscreen printing

-

Multi-touch capacitive touch screen with stylish UI printing

Outdoor Kiosks and Vending Machines: Sunlight Readability, Anti-UV, and Durability

Outdoor or semi-outdoor applications call for:

-

OCA bonding for enhanced contrast under sunlight

-

Anti-UV coatings to prevent yellowing

-

Water- and dust-resistant custom touch panels (IP65+ ready)

-

Touch ICs with glove and water recognition capabilities

Conclusion: Build Better User Interfaces with Custom Touch Screen

Choosing a custom touch screen display ensures your product stands out in performance, durability, and user experience. At Rocktech, we offer full-stack customization—from FPC layout and cover lens design to surface treatment and bonding technology—giving you complete control over both functionality and aesthetics.

Partner with us, a trusted manufacturer with years of experience in delivering high-quality custom display solutions. We understand your application needs and are committed to supporting your product success in today’s fast-evolving markets.

💡 Have a project in mind? Contact us now.