Introduction

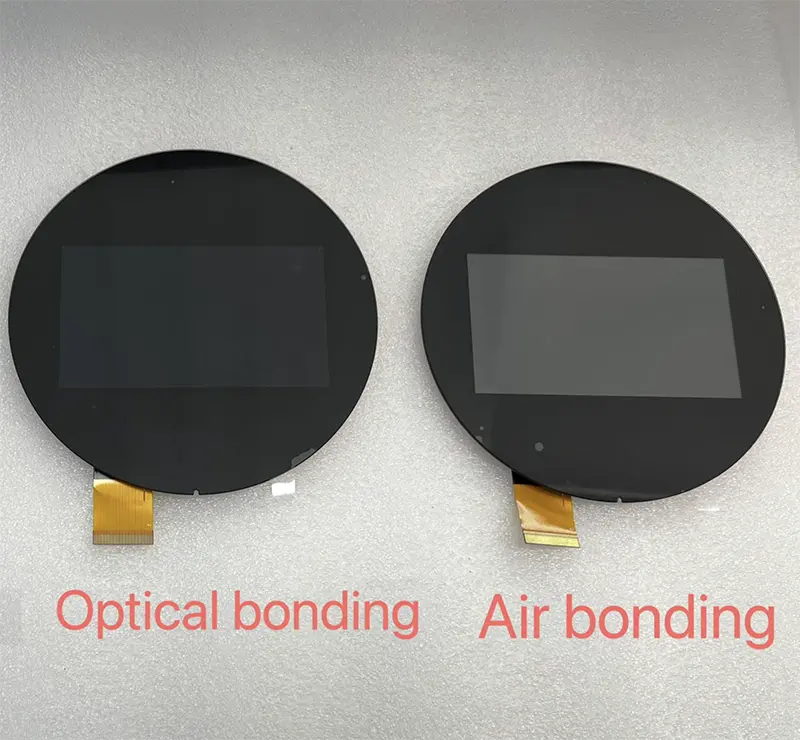

In embedded displays used in industrial LCD systems, medical monitors, and automotive control panels, the bonding method between the LCD panel and its protective glass is a critical design decision. This display bonding method affects not only visual clarity but also durability, sunlight readability, and resistance to shock and moisture.

The two most common bonding techniques are air bonding and optical bonding. Each offers different advantages depending on the application environment. Engineers selecting industrial LCD or embedded display modules must carefully weigh these options to ensure optimal performance in both indoor and outdoor use cases.

What Is Air Bonding?

Air bonding — sometimes referred to as perimeter bonding — is a display bonding method where adhesive is applied only around the edges of the cover glass or touch screen. This leaves a layer of air between the glass and the LCD panel, forming a visible gap.

This method is popular in cost-effective display production due to its simplicity and low manufacturing cost. It is widely used in indoor applications like consumer tablets, touchscreen monitors, and smart home control panels, where strong outdoor visibility or mechanical durability is not essential.

However, the presence of an air gap introduces optical disadvantages — such as internal reflections, poor sunlight readability, and the risk of trapping dust or moisture over time.

Key Benefits of Air Bonding:

- Lower production cost for budget-sensitive projects

- Easier assembly and maintenance in consumer devices

- Suitable for indoor environments with controlled lighting conditions

What Is Optical Bonding?

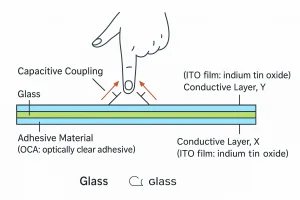

Optical bonding is a display lamination technique in which an optically clear adhesive (OCA or OCR) is used to fully eliminate the air gap between the LCD panel and the protective cover glass. This process bonds the two layers into a single, unified optical unit — a method often referred to as full lamination.

By eliminating internal reflections, optical bonding significantly improves sunlight readability, enhances shock resistance, and increases the structural strength of the display. These advantages make it a preferred choice in rugged and mission-critical applications such as industrial control panels, military-grade tablets, outdoor kiosks, and medical imaging displays.

The enhanced sealing from optical bonding also offers superior protection against moisture, dust, and vibration, which is essential for IP-rated displays used in outdoor or industrial environments.

Key Benefits of Optical Bonding:

- Exceptional sunlight readability, ideal for outdoor interfaces

- Higher contrast ratios with minimal internal reflections

- Enhanced durability in shock, vibration, and moisture-heavy environments

- More accurate touch response due to reduced parallax, critical for HMI and medical touchscreens

4. Air Bonding vs. Optical Bonding: Feature-by-Feature Comparison for Embedded and Industrial Displays

| Feature | Air Bonding | Optical Bonding |

|---|---|---|

| Visual Clarity | Moderate (may have reflections) | Excellent (no internal reflections) |

| Durability | Lower | Higher shock & vibration resistance |

| Sunlight Readability | Poor | Good |

| Moisture Resistance | Poor | Excellent |

| Cost | Low | Higher |

| Use Cases | Consumer electronics | Industrial, medical, outdoor |

Choosing between air bonding and optical bonding has real consequences for performance, especially in industrial and embedded environments. Air-bonded screens often struggle with glare and poor contrast under sunlight, making them less suitable for outdoor kiosks, vehicle dashboards, or field equipment. In contrast, optical bonding significantly improves screen visibility, durability, and reliability in harsh conditions. For environments with high humidity, frequent vibration, or exposure to dust, an optically bonded display ensures long-term stability and fewer maintenance issues.

5. Which One Should You Choose?

The choice between air bonding and optical bonding largely depends on the specific needs of your project.

- For cost-sensitive products such as basic consumer electronics or indoor interfaces, air bonding is often sufficient and provides a lower-cost alternative.

- For applications that require reliability, outdoor visibility, or durability — such as industrial controllers, medical monitors, or vehicle displays — optical bonding is the better option.

It’s also important to consider the long-term return on investment. While optical bonding may require a higher initial cost, it often results in fewer repairs, longer lifespan, and better user experience in demanding environments. For critical embedded systems, the upfront investment in display quality can translate to significant performance and reliability gains over time.

6. Applications and Industries That Require Optical Bonding

Optical bonding technology is widely adopted in applications that demand high reliability, visibility, and environmental resilience. These include:

- Medical equipment such as surgical monitors, where screen clarity and hygiene are critical.

- Industrial HMI panels used in factories, automation systems, and control rooms.

- Military and police-grade tablets (rugged tablets) that require durability under extreme conditions.

- Smart home touch panels that serve as premium interfaces for controlling lighting, HVAC, or security.

- Outdoor displays such as public transport panels, digital signage, and kiosks exposed to sunlight and dust.

In these sectors, optical bonding helps improve safety, user experience, and device longevity — making it an indispensable part of embedded display design.

7. Future Trends and Manufacturing Advancements

As technology advances, optical bonding is becoming more refined and accessible:

- Improved production processes are delivering better yield rates, reducing defects and increasing efficiency.

- New adhesive materials support thinner designs and higher brightness without compromising optical quality.

- Integration with AI and IoT is driving demand for modular, customized bonded displays tailored for smart devices.

These innovations are expanding the scope of optical bonding across various sectors, from wearables to intelligent infrastructure systems.

8. Conclusion

Air bonding and optical bonding each have their place in the display industry. The right choice depends on your product’s priorities — whether cost savings, readability, or durability.

For projects with strict environmental or visibility requirements, optical bonding provides long-term benefits that outweigh its higher upfront cost.

If you’re looking for a display module that supports optical bonding, it’s best to consult with an experienced supplier who can provide technical guidance based on your use case — such as matching it with a Rockchip-powered HMI design.

Frequently Asked Questions about Air Bonding and Optical Bonding

What is the difference between air bonding and optical bonding?

Air bonding leaves a visible air gap between the display and the cover glass, while optical bonding uses optically clear adhesive (OCA or OCR) to eliminate that gap. Optical bonding improves sunlight readability, reduces reflection, and increases durability.

Why choose optical bonding for industrial LCD displays?

Optical bonding enhances visual clarity in bright environments, increases shock and vibration resistance, and prevents moisture or dust from entering the display — making it ideal for industrial, medical, and outdoor embedded display systems.

Does optical bonding affect touchscreen performance?

Yes, optical bonding typically improves touch accuracy by eliminating the parallax caused by the air gap, especially on projected capacitive touchscreens (PCAP). This is important for precision control in embedded applications.

What types of adhesive are used in optical bonding?

Optical bonding uses optically clear adhesive (OCA film) or optically clear resin (OCR liquid). OCA is common in industrial display bonding due to its clean application and high transparency.

Is optical bonding more expensive than air bonding?

Yes, optical bonding typically costs more due to the materials and processing involved. However, its long-term benefits — including improved reliability, readability, and lower failure rates — often justify the investment in critical applications.