1. Introduction: Why Firmware Upgrades Matter for Embedded Android SBCs

In the world of embedded systems, particularly those based on the Android platform, firmware upgrades are not just a convenience—they are a critical component of product lifecycle management. Whether you’re deploying smart panels, industrial HMIs, or edge computing devices, having a robust and reliable upgrade mechanism is essential for maintaining performance, ensuring security, and enabling long-term field support.

Unlike consumer electronics, where devices are frequently replaced or upgraded, embedded Android SBCs (Single Board Computers) are often expected to operate continuously for years in environments where downtime is not acceptable. These systems power everything from factory automation terminals to medical diagnostic displays and agricultural control panels. As such, they must remain up-to-date with the latest security patches, bug fixes, and custom firmware updates tailored to the specific needs of each deployment.

A well-planned firmware upgrade strategy can also reduce operational costs. Rather than recalling hardware for manual re-flashing or maintenance, system integrators can perform remote or automated upgrades—improving uptime, lowering failure rates, and ensuring consistent functionality across distributed devices.

Ultimately, the stability, flexibility, and reliability of the software upgrade process can determine whether an embedded Android device is suitable for industrial deployment. In this guide, we explore the upgrade methods supported by embedded Android SBCs, the technical challenges in real-world scenarios, and how to build a scalable, secure update framework for your project.

2. Upgrade Methods Supported by Android SBCs

Embedded Android systems deployed on single board computers (SBCs) require flexible and reliable methods for firmware upgrades. Depending on the product’s deployment phase, accessibility, and scalability requirements, different upgrade strategies may be applied. This section outlines the most commonly used upgrade methods for Android-based SBCs, along with their typical use cases and technical characteristics.

🔹 2.1 Local SD Card Image Flashing

Local SD card flashing is a straightforward and widely adopted method, especially during the early development phase or factory-level production.

In this approach, a bootable microSD card is prepared with the complete Android firmware image (often in update.img or partitioned image formats). When the SBC is powered on in bootloader or maskrom mode, the bootloader detects the card and flashes the firmware to internal storage.

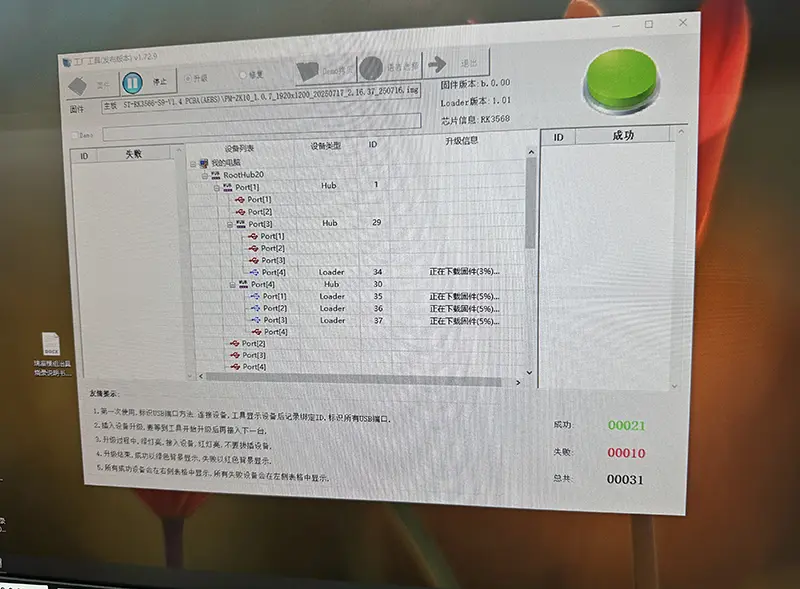

For platforms like Rockchip PX30, RK3566, or RK3588, tools such as RKDevTool, AndroidTool, or upgrade_tool (Linux CLI) are commonly used in conjunction with SD card or USB burning.

Advantages:

-

Fast and reliable for initial production batches

-

No internet or PC connection required once the SD is prepared

-

Can include full system, bootloader, and parameter partitions

Limitations:

-

Requires physical access to the device

-

Not suitable for large-scale field upgrades

🔹 2.2 USB Upgrade via ADB or Fastboot

For developers and integrators working in lab environments or with limited-scale deployments, USB-based upgrades using Android Debug Bridge (ADB) or Fastboot offer a controlled and flexible approach.

With ADB enabled on the device, an engineer can perform incremental updates via adb sideload:

adb sideload update.zipAlternatively, when the device is in Fastboot mode, partition-level flashing is possible:

fastboot flash system system.img

fastboot flash boot boot.img

fastboot reboot

Advantages:

-

Precise control over which partitions to update

-

Useful for debugging, quick patching, or testing new builds

-

No special OTA infrastructure required

Limitations:

-

Requires a USB connection and access to a host PC

-

Must unlock bootloader and enable developer mode

-

Not scalable for remote or unattended deployments

🔹 2.3 Over-The-Air (OTA) Upgrade

Over-the-Air (OTA) upgrades are essential for maintaining deployed products at scale, especially in remote, industrial, or unattended environments.

In this model, the device periodically checks for firmware updates hosted on a secure server. Once a newer version is available, it downloads the OTA package—often signed and compressed—and executes the upgrade process, typically via Recovery or A/B slots.

Android supports two types of OTA:

-

Full OTA: replaces the entire system image

-

Delta OTA (patch): only applies differences, significantly reducing update size

A secure OTA system typically includes:

-

Version tracking logic

-

Encrypted or signed packages (update.zip)

-

Rollback and fail-safe mechanisms

-

Device-side updater (either custom or based on Android’s update_engine)

Advantages:

-

Ideal for field deployments

-

Enables unattended upgrades and remote maintenance

-

Reduces TCO by avoiding manual re-flashing

Limitations:

-

Requires network connectivity (Wi-Fi, Ethernet, LTE)

-

OTA server infrastructure and version control logic must be implemented

🔹 2.4 Custom Script-Based Upgrade

In some specialized use cases—particularly those without a UI, touchscreen, or when minimal user interaction is desired—a script-based upgrade solution is ideal.

These upgrades are often executed via shell scripts, sometimes triggered automatically at boot, by USB insertion, or over network protocols like FTP or MQTT. Tools like BusyBox, recovery shell environments, or custom Android services are used to orchestrate file checks, mount partitions, and trigger updates.

Use cases include:

-

Offline upgrades via USB stick (auto-detected at boot)

-

Environments with no display (e.g., headless gateways)

-

Scheduled upgrades in kiosk or vending machines

Advantages:

-

Fully customizable

-

Works in no-UI or secure-boot environments

-

Lightweight and easy to maintain

Limitations:

-

Requires careful scripting to prevent errors or bricking

-

No rollback support unless implemented manually

-

May require internal access for triggering updates

✅ These upgrade methods can also be combined. For example, a system might support SD card flashing during production, ADB during testing, and OTA in the field—all backed by a robust version control and security model.

3. Real-World Challenges in Industrial Deployment

While Android provides a robust framework for firmware upgrades, implementing and managing updates in industrial environments presents a unique set of challenges. Unlike consumer devices, embedded systems in factories, outdoor installations, or medical settings often operate under strict constraints that limit conventional upgrade methods.

Here are some of the key obstacles encountered during real-world Android SBC deployments:

🔌 Limited or Unreliable Network Connectivity

In many field applications—such as remote agricultural machinery, marine systems, or offline automation terminals—network access may be unavailable or unstable.

-

Devices deployed in factories behind firewalls, or in rural installations, may lack consistent Wi-Fi or LTE coverage.

-

OTA upgrades that rely on downloading firmware packages can fail mid-transfer or become unusable without fallback mechanisms.

Mitigation Strategies:

-

Use preloaded update packages via USB or SD card

-

Implement resumable downloads with version integrity checks

-

Combine local scripts with limited-network polling logic

⚡ Power Interruption Risks

In environments like industrial automation, production lines, or vehicle systems, unexpected power loss during an upgrade can lead to system failure or corruption.

-

Devices powered directly from control systems or batteries may shut down abruptly.

-

If an update is interrupted mid-flash, especially during bootloader or system partition writes, it may leave the device in a bricked state.

Mitigation Strategies:

-

Use A/B system partitions or a backup recovery scheme

-

Include power-loss detection logic (e.g., capacitor-hold + watchdog timer)

-

Verify package before flashing and only begin when battery/stability thresholds are met

4. Case Study: Upgrading Android on a PX30-Based SBC

To better understand the practical considerations of firmware upgrades in embedded Android systems, let’s explore a real-world case involving the PX30-based Single Board Computer (SBC)—a cost-effective, quad-core platform widely used in smart control panels, automation terminals, and custom industrial HMIs.

In this case, a customer deployed over 500 units of Android-based smart panels using PX30 SBCs across multiple locations in a factory automation project. The challenge was to design and implement a reliable, repeatable, and semi-automated upgrade strategy that would minimize downtime and human intervention.

🧩 Initial Conditions & Constraints

-

Devices were installed in wall-mounted enclosures with no USB ports exposed

-

There was no touchscreen or user input device—only Wi-Fi and a status LED

-

Upgrades had to be done remotely, but network connectivity was not always stable

-

The firmware version required patching to fix display refresh and GPIO bugs

🛠️ Selected Upgrade Method: Custom OTA Over Wi-Fi

Given the constraints, the engineering team chose a custom OTA upgrade strategy using:

-

A lightweight version-checking agent running as an Android background service

-

OTA packages hosted on an internal HTTP server

-

A custom shell-based update engine compatible with Rockchip’s partitioning layout

-

PX30 devices with update.zip compatibility and Recovery support

🔁 Upgrade Workflow Overview

The upgrade workflow was designed as follows:

-

Version Query at Boot:

-

Each PX30 board checks /etc/firmware-version and sends a GET request to a central update server.

-

If the server responds with a newer version ID, the upgrade process is triggered.

-

-

OTA Package Download:

-

The OTA file (typically update_v2.1.zip, ~300 MB) is downloaded via HTTP to local storage.

-

A checksum verification (SHA256) ensures file integrity before proceeding.

-

-

Trigger Recovery-Based Upgrade:

-

A small shell script writes upgrade flags and reboots the system into Android Recovery.

-

In Recovery mode, the system installs the update via update.zip, preserving user data.

-

-

Post-Upgrade Validation:

-

After reboot, the system verifies updated services (e.g., display, GPIO).

-

A “success marker” is written back to the server for fleet monitoring.

-

LED flashes green for 10 seconds to indicate success (fallback to red for failures).

-

⚠️ Key Engineering Considerations

-

Fail-Safe Handling:

Devices were configured with boot-time rollback triggers. If the boot process failed more than twice, the PX30 fallback mechanism reverted to the last known good system partition.

-

No UI Upgrade Feedback:

Since there was no screen or touchscreen, the LED was used to communicate upgrade status:

-

Green: success

-

Blinking orange: download in progress

-

Red: failure or timeout

-

-

Power Protection:

Capacitor buffers and bootloader verification logic were added to minimize the risk of brick during power outages.

✅ Result & Outcome

-

Firmware consistency reached 98% across all units within one week

-

Zero physical recalls were required

-

Future firmware updates now follow the same OTA pipeline with automatic scheduling

This case illustrates how a customized OTA upgrade strategy, when properly planned, can transform embedded Android systems from static installations into maintainable, scalable, and field-resilient platforms—without requiring complex infrastructure or user interaction.

5. Planning a Custom OTA System for Your Project

If your embedded Android SBC project involves mass production, remote deployment, or long-term maintenance, it’s crucial to design a custom OTA (Over-the-Air) system from the beginning. A well-structured OTA framework ensures your devices stay up to date, secure, and recoverable—without requiring physical access or costly manual intervention.

Whether you’re developing smart home control panels, industrial terminals, or medical devices, building an upgrade pipeline tailored to your use case will dramatically improve operational efficiency and product reliability.

🧱 Core Components of a Custom OTA System

To implement a robust OTA system for embedded Android devices, the following components are typically required:

-

OTA Package Generator:

-

A build system (e.g., AOSP + Rockchip SDK) that can produce update.zip or delta packages.

-

Support for signing, version tagging, and integrity verification.

-

-

Firmware Hosting Server:

-

HTTP(S)-based server that stores versioned OTA packages.

-

Can be a cloud server, edge server, or LAN-accessible NAS in isolated deployments.

-

-

Version Control Endpoint:

-

An API or static file that devices can query for the latest firmware version (e.g., version.json).

-

Should include update type (critical/optional), URL, checksum, and changelog.

-

-

Update Agent (on-device):

-

A background Android service or native daemon that periodically checks for updates.

-

Responsible for downloading packages, verifying integrity, and triggering Recovery or A/B updates.

-

-

Logging & Rollback Mechanism:

-

Local logs written to persistent storage or sent to a central dashboard.

-

If the upgrade fails, the system should revert to the last known good version.

-

🛠️ Key Design Considerations

-

Minimal User Interaction:

-

For devices with no UI or touchscreen, upgrades must be fully autonomous.

-

Status indicators (LEDs, sound, serial output) can be used for debugging or field diagnostics.

-

-

Bandwidth and Server Load:

-

For large fleets, simultaneous downloads can strain your infrastructure.

-

Use CDN mirrors, staged rollouts, or peer-assisted updates (e.g., LAN sharing).

-

-

Security:

-

Always sign OTA packages and verify signatures before applying.

-

Validate server certificates if using HTTPS.

-

Restrict update servers using IP whitelists or VPN tunnels in sensitive environments.

-

-

Customization & Flexibility:

-

Support for model-specific upgrades (e.g., PX30 vs RK3566)

-

Ability to apply different update schedules or version rules per customer group

-

🤝 Rocktech’s Support for OTA Planning

At Rocktech, we assist OEMs and product developers in planning their own OTA solutions. We offer:

-

Firmware generation with versioning and delta support

-

PX30, RK3566, and RK3588 board customization for OTA compatibility

-

Integration consulting for upgrade agents, secure boot, and remote monitoring

If you’re planning to deploy 100+ Android SBC devices in the field, we highly recommend including OTA upgrade support from day one to reduce future maintenance costs and improve product scalability.

6. Conclusion

Firmware upgrades are a critical part of any embedded Android SBC project—impacting everything from system stability to security and long-term support. Whether you’re building prototypes or managing large-scale deployments, choosing the right upgrade method and planning a scalable OTA strategy can significantly reduce maintenance costs and improve user experience.

By understanding your application’s constraints and selecting the appropriate upgrade mechanism—SD card, ADB, OTA, or script-based—you lay the foundation for a product that can evolve in the field without disruption.

For developers working with platforms like PX30 or RK3566, Rocktech provides the tools, documentation, and engineering support to help you implement reliable firmware upgrade workflows tailored to your product’s needs.