In the fast-paced world of embedded electronics, selecting the right display technology plays a vital role in shaping user experience, device longevity, and power consumption. Among the leading panel options, LCD and OLED stand out with distinct characteristics — especially when used in performance-driven and durable embedded applications. As system requirements evolve, understanding the strengths and limitations of each display type becomes increasingly important for engineers and product designers alike.

This comprehensive guide evaluates both technologies in detail, helping engineers, product designers, and system integrators make informed decisions. Whether you’re building a custom SBC for a medical imaging device or a low-power IoT terminal, understanding these differences is key.

1. Working Principles of LCD and OLED Displays

LCD panels function by using a constant backlight that shines through liquid crystal layers, with each pixel acting as a filter to form images. OLED technology, on the other hand, uses self-emissive organic materials that generate light directly when powered. This core distinction affects factors such as energy efficiency, contrast ratio, and overall display behavior. Understanding how these two technologies differ is essential when selecting components for modern embedded display systems.

- LCDs: Best known for affordability, bright visibility in sunlight, and long production history.

- OLEDs: Valued for deep blacks, vibrant contrast, and wide viewing angles thanks to self-emissive pixels.

In embedded environments such as portable medical devices or industrial HMI panels, these traits can influence power management, readability, and hardware complexity.

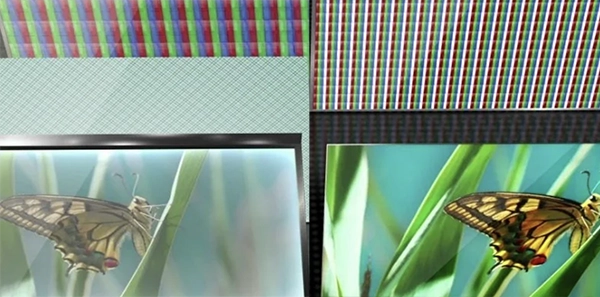

2. LCD vs OLED: Picture Quality Comparison

In the debate of lcd vs oled, OLED panels generally outperform LCDs in terms of picture quality. — particularly in contrast and black levels. Each pixel in an OLED can be turned off completely, offering true blacks that dramatically enhance image depth.

Color reproduction is another major factor. OLEDs often support wider color gamuts and better saturation. However, some users may find OLEDs too vibrant, especially in diagnostic environments that require neutral color balance. LCDs tend to present colors more naturally, which might be preferred for certain medical or industrial interfaces.

Viewing angles also differ: OLEDs maintain color and contrast even when viewed from the side, while LCDs (particularly TN and VA panels) suffer from shifting tones. For multi-angle displays, like medical monitors or kiosk screens, OLEDs may have the upper hand.

In visual-centric applications like multimedia or medical preview screens, LCD vs OLED comparisons consistently favor OLED in contrast performance.

3. Color Accuracy in Embedded Applications

In use cases like radiology or surgery, color fidelity isn’t just a bonus — it’s a necessity. OLEDs offer pinpoint control over brightness per pixel, enabling rich, true-to-source image rendering. But LCDs are closing the gap thanks to technologies like Quantum Dot LCD, which boosts brightness and color consistency.

Proper calibration — via gamma correction and white balance adjustments — can enhance either technology, but OLEDs often need less adjustment out of the box. That said, high-end medical LCDs still dominate the professional display market due to their stability and cost-performance ratio. When comparing LCD vs OLED, color accuracy often comes down to calibration requirements and display consistency over time.

4. LCD vs OLED in Color Accuracy: Critical Considerations

OLEDs offer infinite contrast by completely disabling light output from black pixels. This results in unmatched clarity during dark scenes, ideal for high-dynamic-range content.

LCDs, although incapable of fully disabling backlight at pixel-level, can simulate high contrast through features like Full-Array Local Dimming (FALD). However, these systems are more expensive and add thickness — a drawback in compact embedded devices.

OLED is clearly superior in contrast, but depending on the project, LCD vs OLED trade-offs may still favor LCD for balanced performance.

5. Display Longevity: Burn-in and Lifespan Factors

One of the few weaknesses of OLED is degradation over time — especially of blue sub-pixels — which can result in image retention or burn-in. This is a concern for interfaces with static UI elements like control panels or dashboards.

LCDs don’t suffer from burn-in and generally have longer predictable lifespans, making them ideal for 24/7 operation in kiosks, factories, or hospital monitors. In mission-critical medical applications, stability often trumps aesthetics — giving LCDs the advantage. This makes the choice between OLED and traditional LCD displays especially important for 24/7 interfaces.

6. LCD vs OLED: Power Consumption and Energy Efficiency

Power efficiency is often overlooked in display selection — but for embedded systems, it’s vital. OLEDs consume less power when displaying dark content (e.g., dashboards, black-background UIs). However, power use spikes when showing white or bright colors.

LCDs use a constant backlight, meaning power draw is steady regardless of image brightness. In white-heavy applications — like web browsers or EHR systems — LCD may actually consume less overall energy.

For battery-powered embedded SBCs, consider not only the display type but also expected UI brightness and duration of use.

LCD vs OLED power profiles differ significantly depending on brightness and content type, which must be considered during embedded design.

7. Cost Implications: Is OLED Worth It?

OLED displays are more expensive to manufacture and integrate due to complex supply chains and higher failure rates in production. This often makes them cost-prohibitive for low- to mid-range embedded applications.

LCDs are mature, well-supported, and available in a wide range of industrial sizes and resolutions. For devices targeting cost-sensitive markets — such as smart terminals or remote sensors — LCDs are still the go-to.

However, when the application justifies it — such as premium imaging or wearable diagnostics — OLED is a worthy investment.

8. Which is Better for SBC Projects: LCD or OLED?

Your selection should align with the application’s use case, power budget, environment, and longevity requirements. Here’s a quick comparison:

| Feature | LCD | OLED |

|---|---|---|

| Contrast Ratio | Good (FALD helps) | Excellent (infinite) |

| Color Accuracy | Natural (Quantum Dot enhances) | Vivid & Precise |

| Viewing Angle | Limited on TN/VA | Wide |

| Burn-in Risk | Low | Moderate to High |

| Lifespan | Longer | Shorter (esp. blue pixels) |

| Cost | Lower | Higher |

| Power Efficiency | Even | Variable (depends on content) |

Choosing between LCD vs OLED for embedded SBCs depends not just on specs but also on lifecycle and environmental considerations.

Final Thoughts

There is no one-size-fits-all answer. OLED shines in premium embedded devices where visual impact matters. LCD offers reliability and cost-effectiveness for mission-critical and budget-driven applications. If you’re designing a custom embedded SBC, factor in the intended environment, interface type, UI brightness, and lifecycle requirements.

As display technology continues to evolve, hybrid solutions like Mini-LED LCDs and OLED with anti-burn-in compensation may offer the best of both worlds. For now, smart selection begins with a clear understanding of each panel’s pros and cons. For every embedded project, weighing LCD vs OLED from a lifecycle, cost, and performance perspective is essential.

FAQ: LCD vs OLED Displays in Embedded Systems

Q1: What are the main differences between LCD and OLED displays?

A: LCDs use a constant backlight and are typically more affordable and reliable over time. OLEDs, on the other hand, are self-emissive and provide superior contrast and color vibrancy — but may suffer from burn-in and shorter lifespan.

Q2: Which display technology is better for industrial or medical SBCs?

A: LCDs are often better for long-term use in mission-critical applications like hospital monitors or industrial HMIs due to their longer lifespan and resistance to burn-in. OLEDs are ideal when high contrast and visual appeal are priorities, such as in wearable medical diagnostics.

Q3: Does OLED consume more or less power than LCD in embedded devices?

A: It depends on the UI design. OLED is more power-efficient with dark UIs but consumes more when displaying bright or white-heavy content. LCD maintains steady power use regardless of image content.

Q4: Can LCDs offer good color performance for image-sensitive applications?

A: Yes. With modern enhancements like IPS panels and Quantum Dot technology, LCDs can provide excellent color accuracy and wide color gamuts — often sufficient for medical or industrial imaging tasks.