Capacitive Touch Panels (CTPs) play a vital role in user interface design for embedded and industrial display systems. To ensure optimal mechanical fit and performance, the CTP often requires customization — including shape, bonding method, and IC selection.

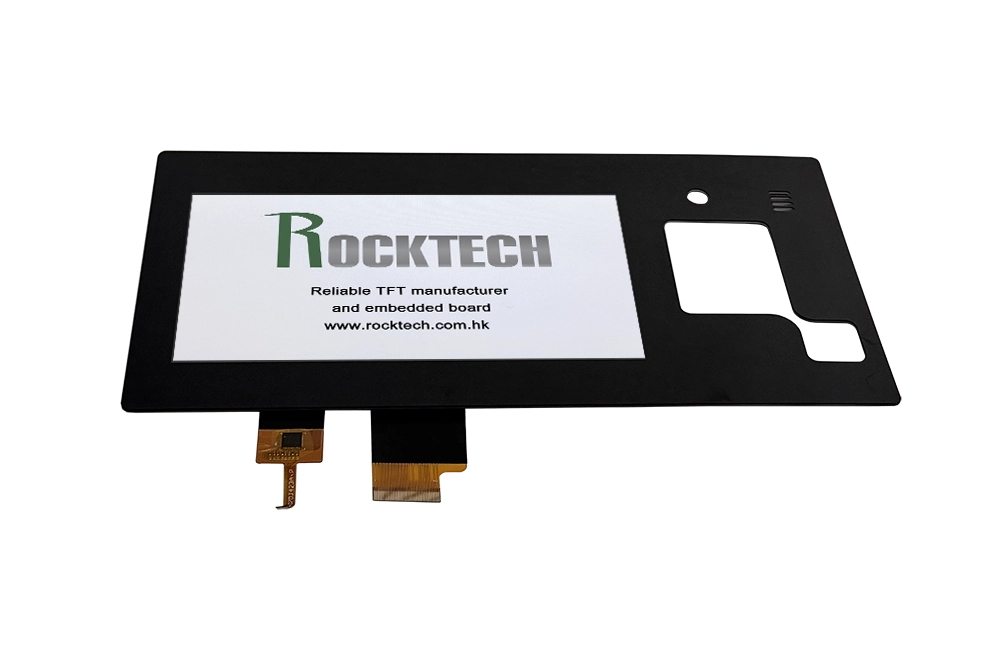

Standard rectangular CTPs may not be sufficient for applications with unique housing, branding, or mechanical needs. Rocktech supports custom designs such as:

These shapes are achieved through laser cutting or CNC processing, and matched with cover glass or plastic overlays as needed. For rugged applications, thicker cover lenses or even Gorilla Glass may be used to enhance durability. This may require stronger Touch ICs capable of driving through thicker materials.

Once the CTP is shaped, it must be bonded to the TFT LCD. There are two common methods:

A clear adhesive (OCA or liquid optically-clear resin) fills the gap between the touch panel and display. Benefits include:

The touch panel is mounted using adhesive only around the frame. It is cost-effective and easier to rework, but has:

High-performance applications may require specific CTP controller ICs to support features like water rejection, glove operation, or high refresh rate. Thicker glass also increases capacitive load, requiring stronger driving capability from the Touch IC.

- Medical Equipment: CTPs with optical bonding and AF coatings for cleanroom use

- Outdoor Terminals: High-transmittance bonding + waterproof touch IC

- Wearables / Compact Devices: Asymmetrical shapes with small cutouts for sensors

- Branded Electronics: Custom logo cutouts and LED indicators integrated into the front

glass

Rocktech provides end-to-end customization of capacitive touch modules — from glass shape and thickness to bonding method and controller IC matching.